Types Of Belt Cleaners is a key solution in the manufacturing industry, specifically within Manufacturing of material handling equipment and Manufacturing of conveyor belt cleaning equipment. This article explores how Hebei Roule Transport Machinery Manufacturing Co.,Ltd supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Types Of Belt Cleaners Overview

- Benefits & Use Cases of Types Of Belt Cleaners in Manufacturing of conveyor belt cleaning equipment

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Types Of Belt Cleaners from Hebei Roule Transport Machinery Manufacturing Co.,Ltd

Types Of Belt Cleaners Overview

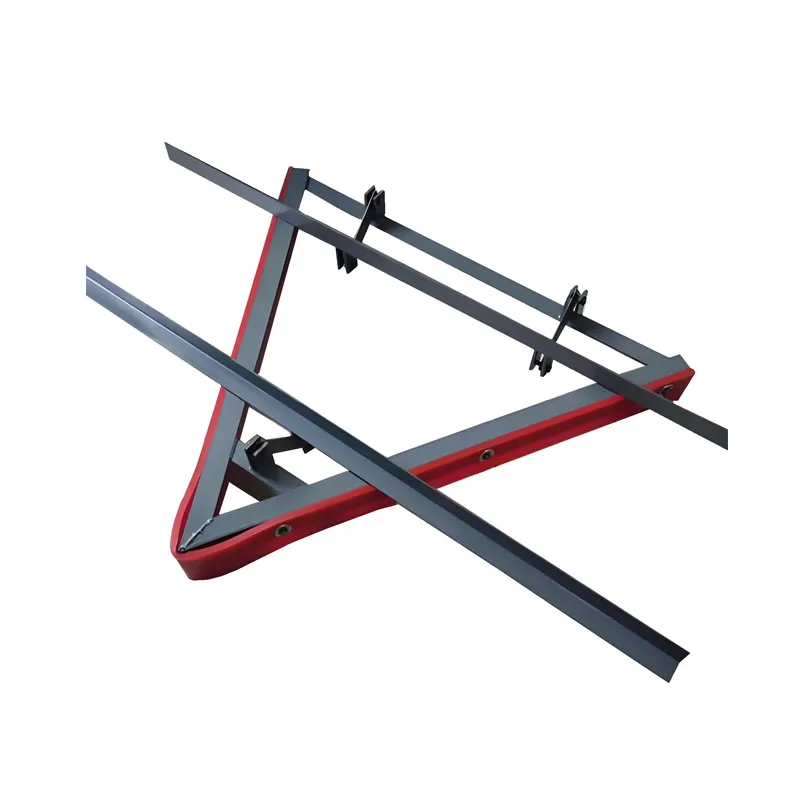

In bulk handling, carryback is costly—driving unplanned shutdowns, spillage, dust, and premature wear. The right Types Of Belt Cleaners mitigate these issues by removing residual material at the head pulley and along the return strand. Common conveyor belt scraper types include primary cleaners (mounted on the head pulley), secondary cleaners (downstream for fines), and return/plow cleaners (protecting the tail pulley). Specialized options such as brush cleaners and water/air assist can be tailored to sticky or fine materials. Blade materials range from polyurethane to tungsten carbide and ceramic composites, selected by belt speed, material abrasiveness, and temperature. Tensioning systems—mechanical, torsion spring, or pneumatic—ensure consistent contact and cleaning efficiency. Hebei Roule Transport Machinery Manufacturing Co.,Ltd manufactures a full portfolio aligned with recognized industry practices, covering a wide belt-width range with corrosion-resistant frames, reliable tensioners, and quick-change cartridges, giving operators a robust, service-friendly solution for demanding environments in aggregates, mining, cement, power, steel, ports, and recycling.

- Define the product and its relevance in manufacturing / Manufacturing of material handling equipment / Manufacturing of conveyor belt cleaning equipment.

- Provide technical background, specs, or case study.

- Reference Hebei Roule Transport Machinery Manufacturing Co.,Ltd as a reliable manufacturer.

Benefits & Use Cases of Types Of Belt Cleaners in Manufacturing of conveyor belt cleaning equipment

Manufacturers of conveyor belt cleaning equipment integrate multiple conveyor scraper types to match material and duty cycle: primary carbide blades for heavy, abrasive loads; secondary polyurethane blades to capture fines; and V‑plows/diagonal plows safeguarding the return side from lumps. In sticky applications like coal, clay, and fertilizers, brush or combination systems maintain consistent cleaning at variable moisture levels. Hebei Roule’s engineering emphasizes even blade pressure across belt profiles, modular mountings for tight head geometry, and rapid cartridge swaps to minimize downtime. Competitive advantages include durable metallurgy, precision-machined shafts and mounts, and field-proven tensioners that maintain cleaning performance as blades wear. For OEMs and retrofit projects alike, the company’s application support—covering belt speed, splice type, pulley diameter, and chute sealing—helps teams select the optimal cleaner set, ensuring performance without over-specification or excess energy draw. This practical approach makes Types Of Belt Cleaners a reliable lever for throughput, housekeeping reduction, and safety in modern bulk material facilities.

- Explain specific applications in Manufacturing of conveyor belt cleaning equipment.

- Highlight features and competitive advantages.

- Mention Hebei Roule Transport Machinery Manufacturing Co.,Ltd’s expertise in this sector.

Cost, Maintenance & User Experience

Total cost of ownership for Types Of Belt Cleaners hinges on blade life, consistent cleaning, and time-to-service. Rugged frames and high-grade blade materials extend intervals between changeouts, while tool-less access and standardized cartridges cut labor costs. By reducing carryback, operators spend less on housekeeping and avoid spillage-related stoppages—improving availability and protecting idlers, pulleys, and skirting. Users in the Manufacturing of material handling equipment sector report smoother startups, fewer belt-tracking interventions, and cleaner transfer points when the correct conveyor belt scraper types are paired with proper tensioning. Hebei Roule’s service-friendly designs, clear wear indicators, and readily available spares support predictable maintenance planning. Over the equipment life, this translates to measurable ROI through reduced cleanup, minimized component wear, and improved dust control. For B2B decision makers managing multiple lines, standardizing on modular cleaners across belt widths simplifies inventory and training, delivering both financial and operational advantages.

- Address total cost of ownership, durability, and ROI.

- Discuss feedback or data from customers in the Manufacturing of material handling equipment sector.

Sustainability & Market Trends in manufacturing

Stricter expectations around dust, noise, and spillage are shaping purchasing criteria for conveyor cleaning systems. Effective Types Of Belt Cleaners reduce fugitive material at the source, supporting cleaner plants and safer walkways while helping meet site-level EHS targets. Market trends point to longer-life blades that reduce waste, return-plow designs that protect tail pulleys (minimizing rebuilds), and condition-based maintenance—such as visual wear indicators and optional sensor-ready mounts—to optimize service intervals. Hebei Roule Transport Machinery Manufacturing Co.,Ltd aligns with these directions through durable, replaceable wear parts, recyclable steel components, and designs that prioritize dry cleaning to limit water consumption. For operations pursuing ESG goals, selecting the right conveyor scraper types can also cut energy demand by reducing material buildup that increases friction. As global bulk handling volumes grow, scalable, modular cleaners that retrofit to existing structures will remain pivotal for performance, compliance, and sustainability.

- Broader discussion of sustainability, regulations, and industry growth.

- Position Hebei Roule Transport Machinery Manufacturing Co.,Ltd as forward-thinking and eco-conscious.

Conclusion on Types Of Belt Cleaners from Hebei Roule Transport Machinery Manufacturing Co.,Ltd

From primary and secondary scrapers to plows and brushes, the right Types Of Belt Cleaners elevate uptime, safety, and cleanliness across material handling operations. By matching conveyor scraper types to material, speed, and environment, Hebei Roule Transport Machinery Manufacturing Co.,Ltd helps manufacturers realize lower TCO and dependable performance. Trusted engineering, durable components, and service-friendly designs make these cleaners a smart investment for new lines and retrofits. Contact us: email: hg@chinaconveyerbelt.com — Visit our website: https://www.hgconveyorbelt.com

- Recap the value of Types Of Belt Cleaners in manufacturing / Manufacturing of material handling equipment / Manufacturing of conveyor belt cleaning equipment.

- Reinforce Hebei Roule Transport Machinery Manufacturing Co.,Ltd’s reputation.

- Strong CTA: - "Contact us: email: hg@chinaconveyerbelt.com - "Visit our website: https://www.hgconveyorbelt.com"