- Tel: +8615128135888

- Email: hg@chinaconveyerbelt.com

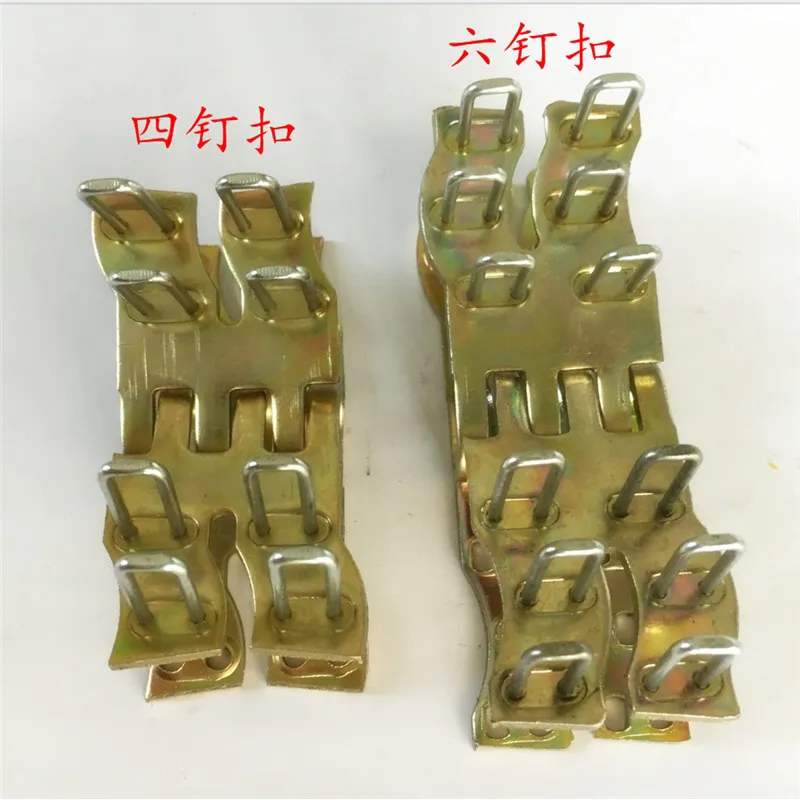

Six Nail Buckle

The conveyor belt connecting buckle is a key mechanical component used to connect the ends of the conveyor belt, forming a circular closed structure through rigid fixation to ensure the stability and load-bearing capacity of the conveyor belt during continuous operation.

Structure And Material Of Conveyor Belt Connection Buckle

Usually made of high-strength metals such as alloy steel and stainless steel, it has wear resistance, tensile strength, and rust prevention properties. Some models adopt a double needle or one-piece design to enhance connection stability.

Functional Characteristics Of Conveyor Belt Connection Buckle

Through mechanical fixation (such as steel nails, riveting) or modular buckle methods, seamless connection of the belt can be quickly achieved, avoiding the complex process of traditional vulcanization technology and reducing the risk of fracture caused by uneven local stress.

Classification Of Types Of Conveyor Belt Connection Buckles

Divided By Structure And Applicable Scenarios:

Functional type: such as adjustable buckle, buffer buckle, suitable for high impact or easy deviation scenarios;

Form: including butterfly buckle, wolf tooth buckle, needle buckle, zipper buckle, etc., to meet different belt thicknesses and load requirements.

Conveyor belt connecting buckles are widely used in high-strength industrial scenarios such as mining, logistics, and cement, especially suitable for scenarios that require frequent belt replacement or maintenance, balancing efficiency and economy.

The installation method of the conveyor belt connection buckle is to fix the connection buckle to a dedicated mold or lower template, insert the positioning pin, and ensure that the two ends of the conveyor belt are symmetrical and fully fit the bottom surface of the buckle after insertion.

Mechanical buckle (needle buckle/wolf tooth buckle): First fix the buckle at the center position, then install the buckles near the sides of the belt in sequence, and finally evenly nail the remaining buckles from the middle to the left and right.

High-Performance Conveyor Belt Six Nail Buckle – Engineered for Reliability

High-Performance Conveyor Belt Six Nail Buckle – Engineered for ReliabilityThis advanced six-nail buckle system offers 50% greater fastening power compared to standard four-nail designs, making it ideal for wide or thick conveyor belts. The precision-engineered nail pattern distributes stress evenly across the belt width, preventing edge damage and elongation.

Let's Get in Touch!

Send us a message and let our experts assist you with tailored solutions.