- Tel: +8615128135888

- Email: hg@chinaconveyerbelt.com

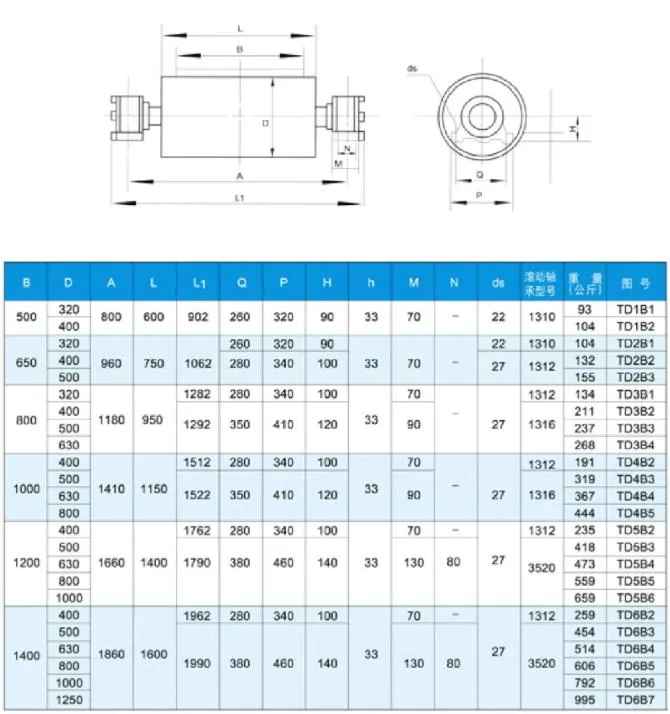

Transmission Conveyor Drum

The specifications of the reversing drum include light, medium, and heavy, corresponding to different diameter ranges: 50-100mm, 120-180mm, and 200-260mm. The structural type of the reversing drum is consistent with that of the transmission drum.

The structure of the reversing pulley mainly includes drum shell, drum bearings, drum end caps, motors, and transmission devices. The drum shell is usually made of steel plate, used to support and protect the internal components of the drum, and bear the weight of the transported goods. The drum bearing is the core component of the reversing drum, usually using two ball shaped roller bearings with high load-bearing capacity and wear resistance. The drum end caps are fixed at both ends of the drum, usually made of cast iron or steel plate, to protect the drum bearings and prevent dust and moisture from entering the inside of the drum. The motor and transmission device are the driving components of the reversing drum, usually using a combination of electric motor and reducer to provide sufficient power to ensure smooth operation of the drum.

The working principle of the reversing drum is to use the bearings and transmission device in its structure to enable the drum to rotate smoothly, thereby changing the direction of the conveyor belt's movement. Specifically, the reversing drum is installed at the end of the conveyor belt or at a location where the direction of the conveyor belt needs to be changed, and its structural design enables the conveyor belt to smoothly change direction. The surface of the reversing drum is usually covered with rubber to increase the friction coefficient with the conveyor belt and ensure stable transmission effect.

The main application scenarios of the reversing drum are power plants, ports, mines, metallurgy, building materials and other departments, widely used in situations where the direction of the conveyor belt needs to be changed.

Heavy-Duty Directional Conveyor Drum – Built for Industrial Demands

Heavy-Duty Directional Conveyor Drum – Built for Industrial DemandsConstructed with thick-grade steel shells and reinforced end discs, our drums withstand the stress of high-tension directional changes in mining and port applications. The precision-machined grooves prevent belt slippage during turns.

Let's Get in Touch!

Send us a message and let our experts assist you with tailored solutions.