- Tel: +8615128135888

- Email: hg@chinaconveyerbelt.com

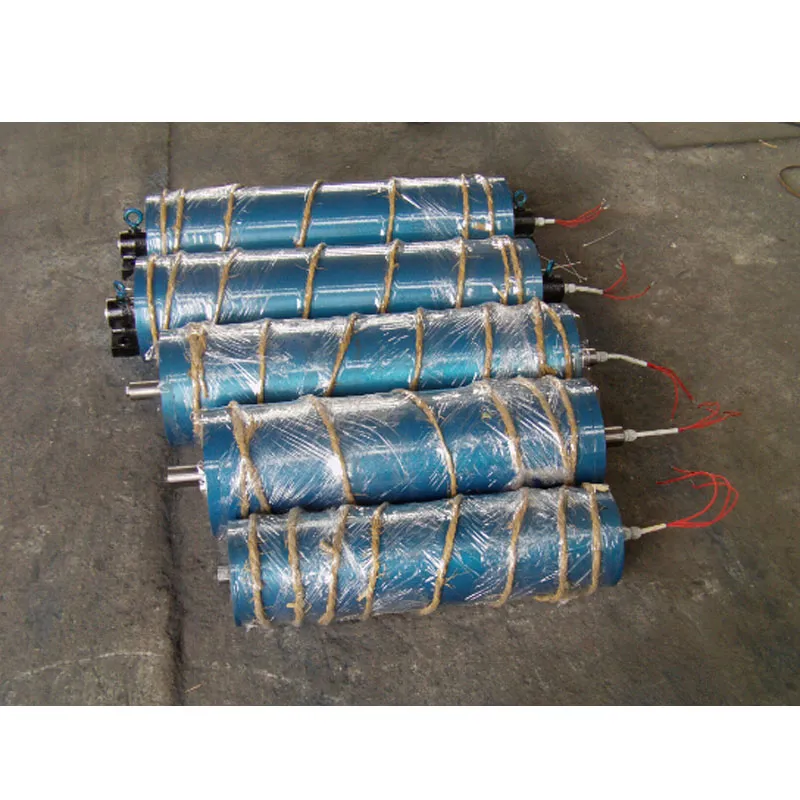

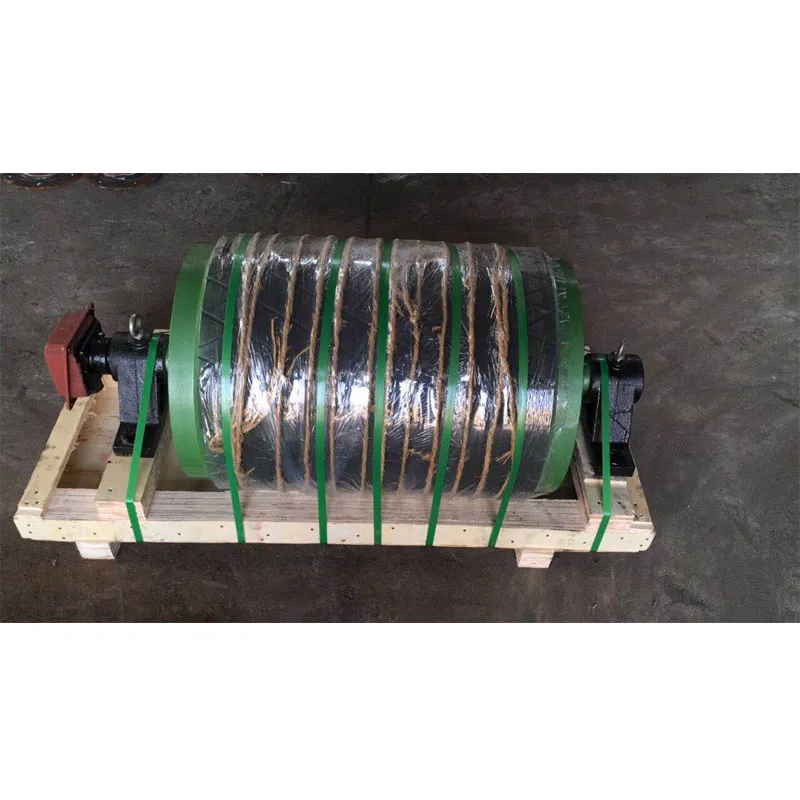

Built in Electric Conveyor Drum

Electric drum has many advantages such as compact structure, high transmission efficiency, low noise, long service life, smooth operation, reliable work, good sealing, small space occupation, easy installation, etc., and is suitable for working in various harsh environmental conditions.

Working Conditions Of Built-in Electric Drum:

1.The operating environment temperature is 15 ℃+ 40℃;

2.Altitude not exceeding 1000 meters;

3.The temperature of the conveyed material shall not exceed 60 ℃;

4.Voltage 380V, frequency 50Hz.

Electric rollers, as the power source for belt conveyors and lifting equipment, are widely used in sectors such as mining, metallurgy, chemical industry, coal, building materials, electricity, grain, and transportation.

1.It can replace the widely used motor reducer type external drive device to form a belt conveyor, which can transport bulk materials such as coal, ore, sand, cement, flour, as well as bulk items such as burlap and equipment.

2.The structure is simple and compact, occupying a small space area.

3.Good sealing, suitable for workplaces with high dust concentration, damp and muddy conditions.

4.Easy to use and maintain, safe and reliable to operate, with a long lifespan.

5.Low energy consumption and easy to achieve centralized control.

6.It can meet various needs such as reverse, braking, and rubber wrapping.

Smart Electric Conveyor Drum – Plug-and-Play Automation Ready

Smart Electric Conveyor Drum – Plug-and-Play Automation ReadyFeaturing variable frequency control and IoT connectivity options, this self-contained drum enables precise speed adjustment and remote monitoring. The sealed housing protects internal components from dust and moisture in harsh plant environments.

Let's Get in Touch!

Send us a message and let our experts assist you with tailored solutions.