- Tel: +8615128135888

- Email: hg@chinaconveyerbelt.com

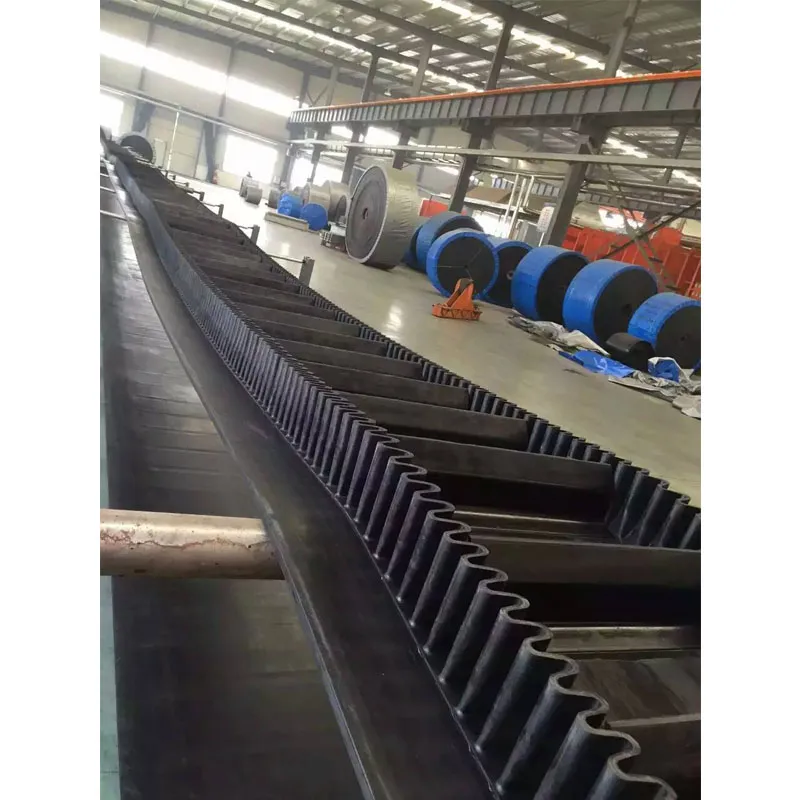

Large Angle Corrugated Edge Conveyor Belt

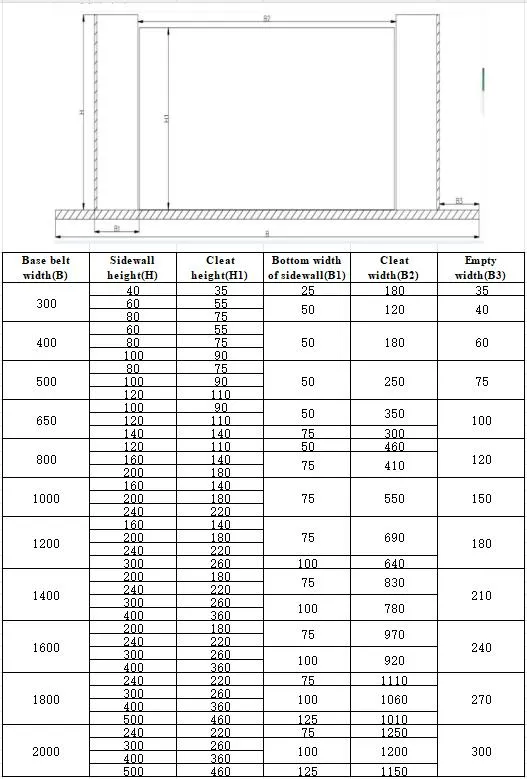

The high inclination conveyor belt can stably transport materials at large inclination angles, even up to 90 °, suitable for steep slopes and vertical conveying needs, greatly saving space.

Drive device: It is the power part in the conveyor. The system consists of a Y series electric motor, a ZJ type shaft mounted reducer, and a wedge type backstop.

Drive drum: It is the main component for power transmission, and the conveyor belt runs through the friction between it and the drive drum. This series of transmission rollers can be divided into rubber surface and smooth surface. Rubber surface rollers are used to increase the adhesion between the roller and the conveyor belt.

Reversing drum: used to change the running direction of the conveyor belt. The reversing drum is used for the lower surface of the conveyor belt (non bearing surface).

Belt roller: used to change the running direction of the conveyor belt, the belt roller is used on the upper surface (bearing surface) of the conveyor belt.

Roller: Roller is used to support the conveyor belt and the materials on it, ensuring its stable operation. This series has two types of rollers: upper parallel rollers and lower flat rollers.

Belt roller: The belt roller is used to support the lower branch of the conveyor belt on the convex arc section frame, and is supported on the empty edges on both sides of the edge conveyor belt. Several sets of belt rollers form a circular arc segment for changing the direction of the conveyor belt. The supporting roller adopts cantilever support. Vertical roller: The vertical roller is used to limit the deviation of the conveyor belt and is installed on the upper and lower transition section frames. Each filtering section rack is equipped with four, with two on top and two on the bottom.

Beating wheel cleaning device: used to pat the back of the conveyor belt and shake off the material stuck on the conveyor belt.

Tightening device: Its function is to provide sufficient tension to the conveyor belt, ensuring that there is no slippage between the conveyor belt and the drive drum. 2. Limit the verticality of the conveyor belt between the supports to ensure normal operation of the conveyor. This series uses a spiral tensioning device. Rack, head funnel, head cover, guide groove, middle frame, middle frame legs, etc.: They play a supporting, dustproof, and guiding role in the conveyor respectively. There are three types of middle frame legs in this series: low, medium, and high. The lower and inclined sections are only equipped with low style middle frame support legs, while the upper and lower horizontal sections are equipped with different middle frame support legs (low style, Chinese style, and high style middle frame support legs) according to different headrests (low style, Chinese style, and high style).

The Scope Of Use Of High Inclination Conveyor:

① It can be widely used in industries such as coal, grain, building materials, construction, metallurgy, electricity, chemical, and light industry.

② It can transport various bulk materials with a bulk density of 0.5-2.5t/m ³ within an environmental range of -25~40 ℃.

③ The maximum conveying angle is 90 °, and the maximum block size of the conveyed material is 550mm.

Heavy-Duty Corrugated Belt – Engineered for Maximum Material Retention

Heavy-Duty Corrugated Belt – Engineered for Maximum Material RetentionFeaturing reinforced sidewalls and flexible corrugations, this belt maintains structural integrity while handling abrasive loads at steep inclines. The unique wave pattern significantly increases capacity compared to conventional inclined conveyors.

Let's Get in Touch!

Send us a message and let our experts assist you with tailored solutions.