- Tel: +8615128135888

- Email: hg@chinaconveyerbelt.com

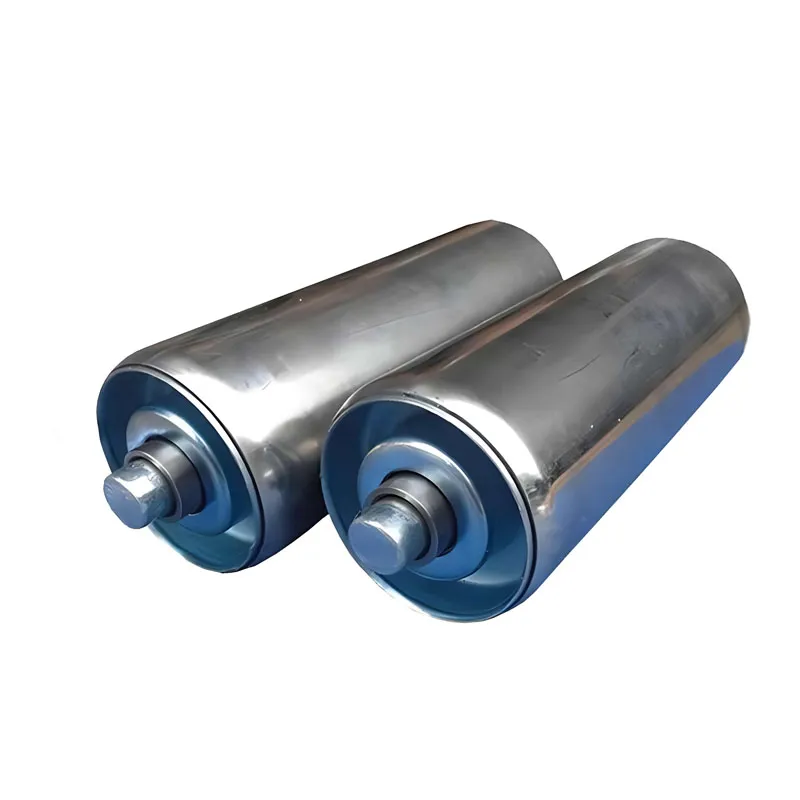

Stainless Steel Conveyor Roller

Stainless steel conveyor rollers made of stainless steel are important components in conveyor lines. There are many types of stainless steel conveyor rollers, so different stainless steel conveyor rollers can be customized according to the needs of different industries. Therefore, when choosing stainless steel conveyor rollers, the best solution should be selected based on the actual production situation of the industry.

The Advantages Of Stainless Steel Rollers Mainly Include The Following Aspects:

Rust and magnetic resistance: Stainless steel rollers are made of high-quality stainless steel material, which has good rust and magnetic resistance and is suitable for environments such as underground or power plants that are prone to moisture and corrosion.

Wear resistance: Stainless steel rollers have excellent wear resistance and can extend their service life.

Corrosion resistance: Stainless steel rollers have good corrosion resistance and can adapt to humid, acidic and alkaline environments, maintaining long-term rust and corrosion resistance.

High hardness and strength: Stainless steel rollers have good hardness and strength, suitable for equipment environments with high load-bearing requirements, and can maintain stable performance for a long time.

Easy to clean and maintain: The surface of the stainless steel roller is smooth and not easily adhered to dust and impurities, making cleaning and maintenance very convenient.

Good Aesthetics: The surface of the stainless steel roller presents a metallic luster, which has excellent aesthetics and can maintain its beauty for a long time.

Anti static and low damping sealing structure: Stainless steel rollers have anti-static and low damping sealing structures, which can protect the safety and reliability of conveyor belts, reduce power consumption, and improve equipment energy efficiency.

The application scenarios of stainless steel rollers mainly include: under the iron remover of underground or power plant belt conveyors: stainless steel rollers are used to prevent the rollers from being sucked up by the iron remover and are suitable for humid and corrosive environments.

Other occasions that require high wear resistance and corrosion resistance: Due to the excellent performance of stainless steel rollers, they are also suitable for other occasions that require high wear resistance and corrosion resistance, such as pharmaceutical and food manufacturing industries.

Hygienic Conveyor Roller Solution – Perfect for Sanitary Applications

Hygienic Conveyor Roller Solution – Perfect for Sanitary ApplicationsFeaturing seamless construction and FDA-compliant materials, these rollers meet strict cleanliness standards in pharmaceutical and food production. The easy-clean design prevents bacterial growth.

Let's Get in Touch!

Send us a message and let our experts assist you with tailored solutions.