- Tel: +8615128135888

- Email: hg@chinaconveyerbelt.com

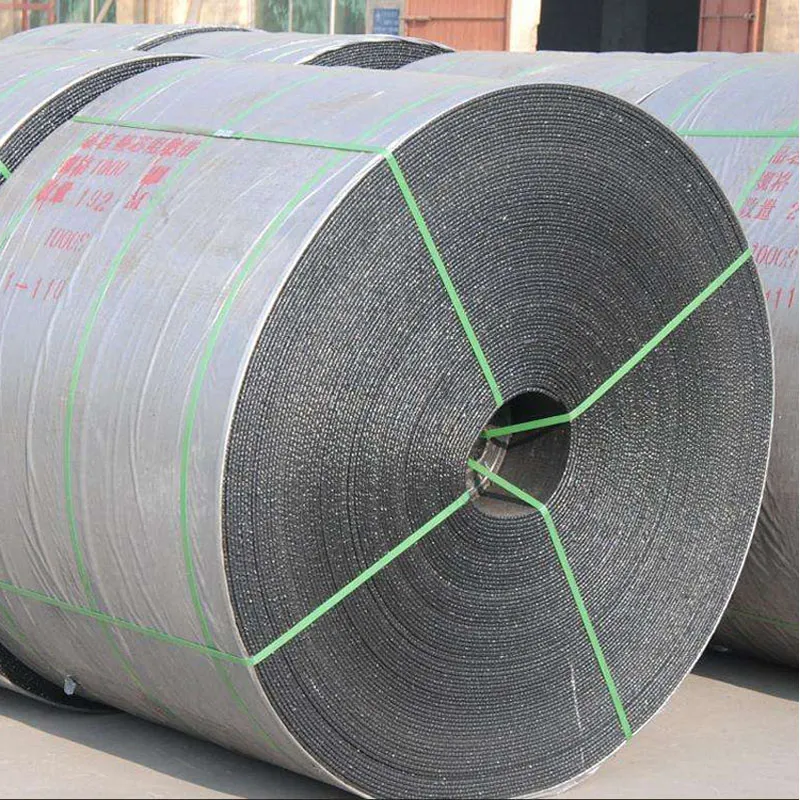

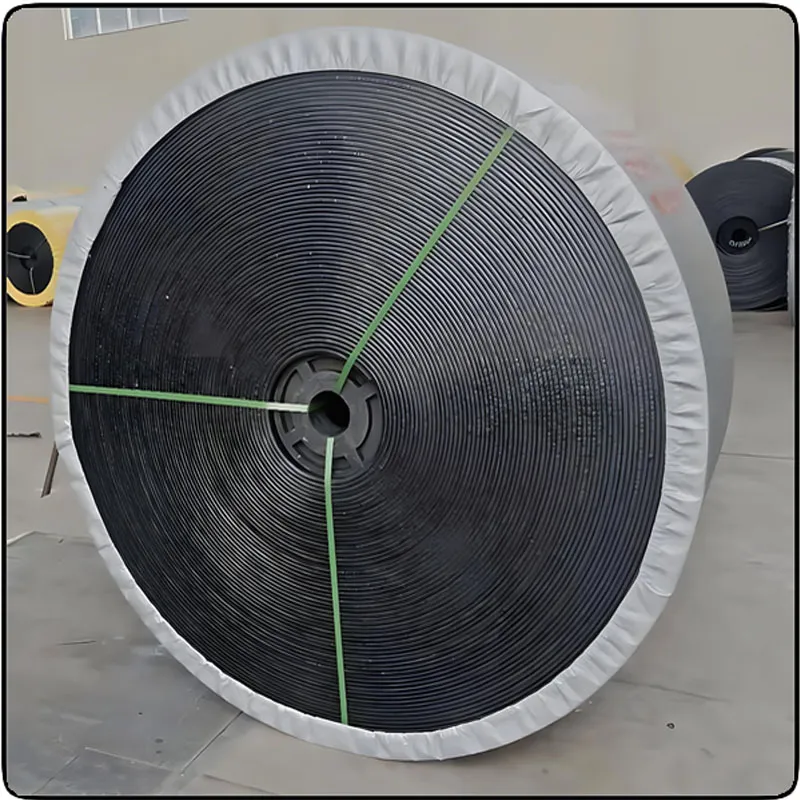

Whole Core Flame-retardant Conveyor Belt

The flame-retardant conveyor belt is mainly suitable for underground transportation in coal mines, and can also be used for material transportation in metallurgy and chemical industries. The whole core flame-retardant conveyor belt can be divided into PVC type and PVG type.

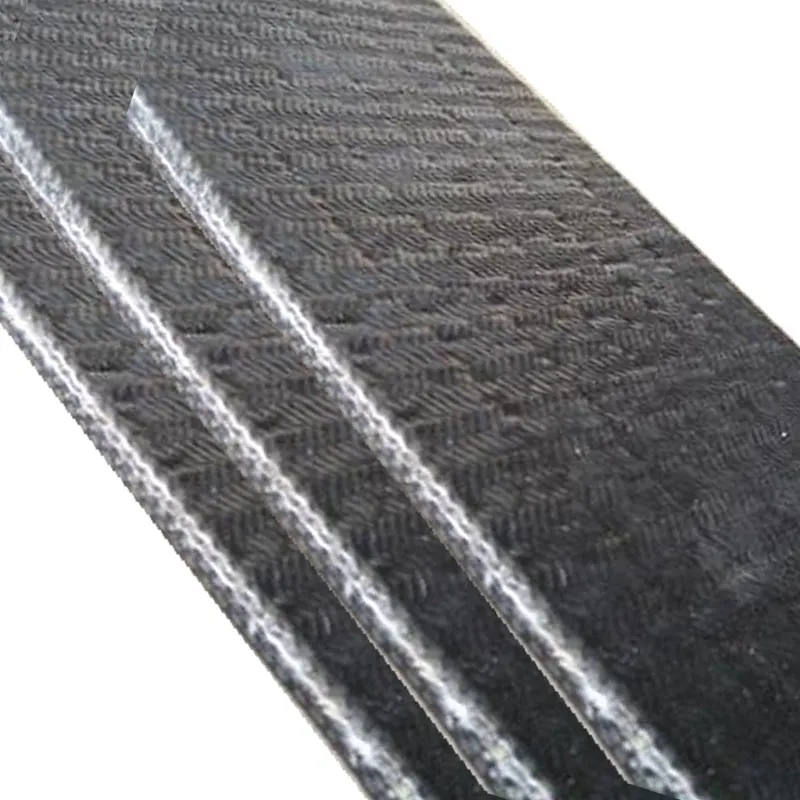

Flame retardant conveyor belt, also known as whole core flame retardant conveyor belt, is made by impregnating and plasticizing or vulcanizing the whole belt core with polyvinyl chloride impregnated paste. It has the characteristics of high strength, large capacity, and balanced transportation. At the same time, this product has good flame retardant, anti-static, impact resistant, wear-resistant, and corrosion-resistant properties. The upper and lower covering layers of PVC type are both made of PVC cover adhesive, with single-sided adhesive ≥ 0.8mm; The upper and lower covering layers of PVG type are both made of nitrile rubber and PVC, with a thickness of 1.5mm-4.5mm on one side. PVC conveyor belts with an inclination angle of less than 16 ° and PVG conveyor belts with an inclination angle of less than 20 ° can both be used for transportation above and below coal mines.

Production process of flame-retardant conveyor belt: drying → plasticizing → compounding → mixing → parking → hot refining → rolling → forming → vulcanization → packaging. Unlike non nylon skeleton conveyor belts, the production process of nylon layered flame-retardant conveyor belts requires secondary stretching and shaping treatment after vulcanization. There are two main methods for secondary stretching and shaping: one is the cooling and shaping method under mold pressure (hereinafter referred to as mold shaping), and the other is the stretching and cooling shaping method outside the mold (hereinafter referred to as mold shaping). The method of in mold shaping is simple and the shaping effect is good. However, using this method for shaping consumes a lot of energy and has low production efficiency. In contrast, although the external molding method requires an additional set of stretching devices, the product quality is reliable and the production efficiency is high after using this method, making it suitable for large-scale production.

Enhanced Durability & Fire Resistance – Reliable Performance Under Pressure

Enhanced Durability & Fire Resistance – Reliable Performance Under PressureUnlike surface-treated alternatives, our whole-core design provides consistent flame resistance throughout the belt’s entire structure. It maintains strength and flexibility even under heavy loads, reducing the risk of tears or failures in critical operations.

Let's Get in Touch!

Send us a message and let our experts assist you with tailored solutions.