- Tel: +8615128135888

- Email: hg@chinaconveyerbelt.com

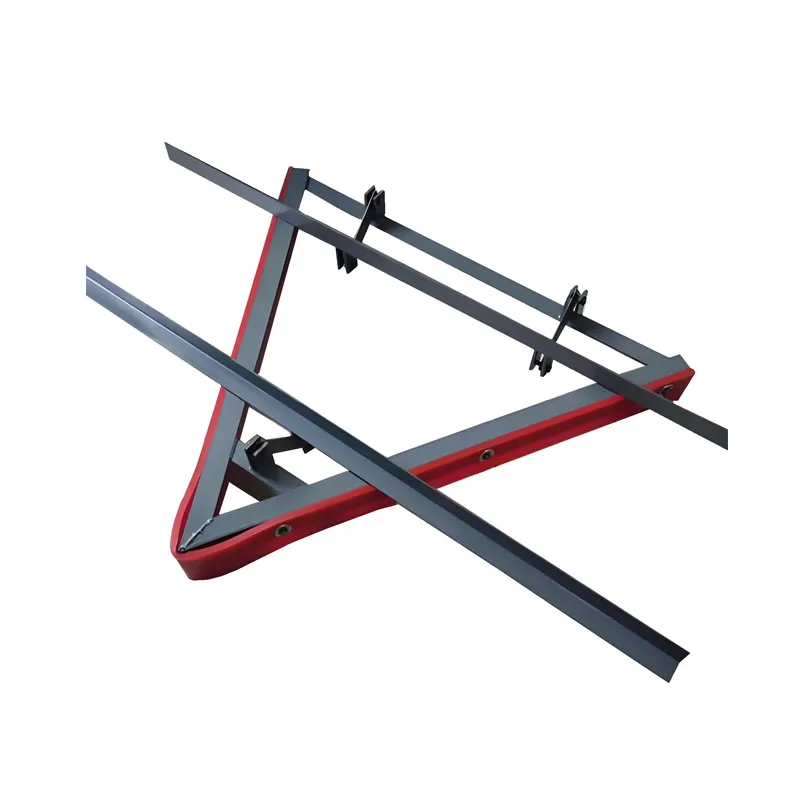

Nonloaded Cleanser for Belt Conveyor

The empty section cleaner is suitable for cleaning non working surfaces of conveyor belts. The cleaning scraper uses wear-resistant rubber plates, and its blade head is wear-resistant, corrosion-resistant, and resistant to breakage without damaging the belt, ensuring high safety; The parallel mechanism frame can make the cleaner tightly adhere to the conveyor belt, and can automatically adjust the position of the cleaner according to the wear of the cleaning blade and changes in the position of the conveyor belt. The cleaning is clean and effective, and the structure is simple and easy to maintain.

The materials conveyed by conveyor belts often contain viscous substances, such as coal dust, mud, and powdered materials. Some of them will stick to the working surface of the conveyor belt and cannot be completely unloaded. As the belt runs, they will stick to the rollers, which can cause the following consequences over time:

- When the material enters the shell of the roller, it increases the wear of the bearing. If the material sticks to the roller shell, it will damage and strain the surface adhesive of the conveyor belt, accelerating the damage of the conveyor belt.

- When the adhesive enters the tail wheel and the reversing drum, the material will stick to the surface of the drum, and the more it sticks, the more it will cause the conveyor belt to deviate, increase the wear of the conveyor belt, and lead to adverse consequences.

- The material sticking to the driving drum increases the friction on the drum, which can cause damage to the conveyor belt surface adhesive and drum coating layer.

- If materials are not cleared in a timely manner, a falling area will form throughout the entire work channel, causing environmental pollution, increasing the amount of cleaning labor, affecting the physical and mental health of employees, and increasing enterprise costs.

Therefore, in order to ensure the normal operation of the belt conveyor, it is necessary to clean the attachments on the conveyor belt. If the cleaning device is in good condition, the lifespan of the rollers, conveyor belts, etc. can be extended.

Therefore, it is necessary to install an empty section cleaner at the inlet of the reversing drum and the tail drum during the return journey.

Heavy-Duty Nonloaded Cleanser – Protecting Your Conveyor Investment

Heavy-Duty Nonloaded Cleanser – Protecting Your Conveyor InvestmentEngineered for maximum durability, this Nonloaded Cleanser features advanced polyurethane blades that provide thorough cleaning without damaging belt surfaces. The unique mounting system allows easy installation and maintenance while accommodating different belt widths and speeds.

Let's Get in Touch!

Send us a message and let our experts assist you with tailored solutions.