- Introduction: Overview of the concrete conveyor for sale

market and its impact on construction efficiency - Market Trends and Demand: Statistical insights and projections for concrete conveyor systems

- Technical Advantages of Modern Concrete Conveyor Belts

- Portable Concrete Conveyor Innovations and Mobility Benefits

- Leading Manufacturers Comparison: Data-driven table analysis

- Customization Options and Buyer Considerations

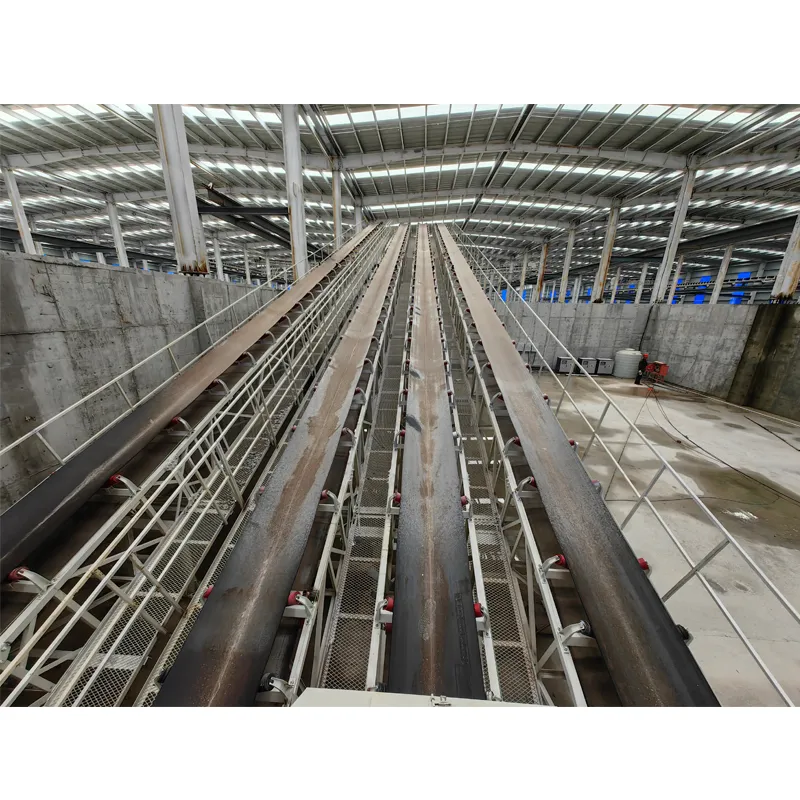

- Case Studies: Concrete Conveyor for Sale in Real Construction Applications

(concrete conveyor for sale)

Unveiling the Power of the Concrete Conveyor for Sale Market

The surge in demand for concrete conveyor for sale platforms is fundamentally changing the operational landscape of modern construction sites. In a fast-paced industry that routinely faces tight deadlines and complex logistical challenges, construction managers are increasingly turning towards advanced concrete conveyor systems, including fixed and portable concrete conveyor models, to boost overall efficiency. Studies indicate that automating material transport can expedite concrete placement by up to 35%, directly impacting labor productivity and project timelines. As developers and contractors position for a competitive edge, understanding the evolution, benefits, and strategic purchase decisions surrounding concrete conveyors is more crucial than ever.

Market Trends and Demand for Concrete Conveyor Systems

Over the last decade, the global construction sector has seen a notable uptick in the adoption of concrete conveyor belt technologies. According to a 2023 market analysis from Allied Market Research, the worldwide market for conveyor systems in construction is projected to reach $13.7 billion by 2028, registering a CAGR of 6.2%. Key growth drivers include rapid urbanization, rising infrastructure investments, and increasing demand for precast construction methods. North America and Asia-Pacific regions lead the market, with a combined market share exceeding 65%. For contractors handling large-scale commercial or civil engineering projects, investments into versatile conveyor solutions are enabling higher throughput and improving site logistics, especially when compared to conventional material delivery methods.

Technical Advantages of Modern Concrete Conveyor Belts

Innovations in concrete conveyor belt engineering have significantly enhanced the performance and reliability of current-generation systems. Contemporary belts utilize wear-resistant synthetic polymers, reinforced with steel mesh, to sustain high loads and abrasive aggregates. The integration of variable frequency drives (VFDs) offers precise control of conveyor speed, allowing operators to optimize material flow depending on project-specific needs. Compared to traditional bucket-and-crane placements, modern conveyor systems are capable of moving between 80 to 150 m³ of concrete per hour over distances up to 60 meters horizontally and 25 meters vertically (manufacturer data, 2023). In addition, sensors and automation facilitate real-time monitoring of belt tension, temperature, and concrete consistency, thereby minimizing operational downtime and reducing maintenance interventions by as much as 20%.

Portable Concrete Conveyor Innovations and Mobility Benefits

The rise of portable concrete conveyor units marks a major leap in onsite material handling. Designed for ease of deployment and rapid relocation, portable conveyors deliver unique value on tightly constrained or multi-phase job sites where flexibility is prioritized. Thanks to lightweight alloy frames and modular assembly, typical setup times have decreased from several hours to under 30 minutes. Mobile conveyors can transport concrete, sand, and aggregates over uneven terrain, helping contractors to tackle complex pours and improve site safety by minimizing material spillage and manual transport. Innovations such as extendable boom lengths (up to 18 meters) and 360-degree rotational bases further expand the operational envelope, making them indispensable for projects that demand both speed and adaptability.

Leading Manufacturers Comparison: Data-Driven Table Analysis

Selecting the most appropriate conveyor unit requires a data-focused assessment of leading industry suppliers. Below is a comparative table highlighting key differentiators among top manufacturers:

| Manufacturer | Model | Conveyor Type | Max Throughput (m³/hr) | Max Range (m) | Setup Time | Automation Features | Typical Price Range (USD) |

|---|---|---|---|---|---|---|---|

| Rotec Industries | Super Swinger 1050 | Mobile | 120 | 18 | ~30 min | VFD, Sensors | 78,000–115,000 |

| Liebherr | THS 80 D4F | Stationary | 150 | 24 | ~2 hr | Fully automated | 145,000–212,000 |

| Terex | C2050 Series | Portable | 95 | 17 | ~25 min | Remote Control | 68,000–102,000 |

| Telebelt (Putzmeister) | TB 110 | Truck-Mounted | 104 | 32 | ~40 min | Hydraulic, VFD | 123,000–189,000 |

Notably, newer models are equipped with extended warranty packages, digital interfaces for diagnostics, and enhanced durability for abrasive materials. Price considerations are balanced by long-term performance and reduced maintenance costs, factors critical for contractors focused on lifetime value.

Customization Options and Buyer Considerations

Adaptability and customization are decisive for maximizing the potential of concrete conveyor belt systems. Buyers can select from an array of options, including belt width (ranging typically from 400 mm to 800 mm), frame material (aluminum or galvanized steel), and drive unit configurations (electric, diesel, or hybrid). Many suppliers offer modular conveyor segments, allowing users to extend or reposition systems as project demands shift. Site conditions—such as grade incline, weather exposure, and required range—should always inform these choices. Safety features, including emergency stop systems, side guards, and anti-slip walkways, are increasingly mandatory for compliance and workforce protection. Detailed consultation with manufacturers can yield tailored solutions—such as integrated spray systems for dust suppression or cold-weather reinforced belts—for unique operational challenges.

Concrete Conveyor for Sale: Real-World Application Case Studies

Implementing a concrete conveyor for sale into demanding build environments has consistently demonstrated tangible benefits. In a 2022 infrastructure renewal project in Chicago, deploying a 24 m steel-belted conveyor enabled a 28% reduction in foundation pour times and cut manual labor needs by nearly half. Similarly, a civil engineering team in Sydney utilized a portable concrete conveyor while constructing a complex urban viaduct, achieving consistent placement over a 900-meter stretch without repeated repositioning of equipment—minimizing disruption in a densely populated zone. Coupled with real-time monitoring, these solutions have also led to a 15% decrease in material waste. For contractors seeking to boost productivity, ensure quality, and drive project profitability, concrete conveyor systems have become a vital investment that transforms jobsite performance and profitability.

(concrete conveyor for sale)