Driving Industrial Efficiency: The Core of Conveyor Systems

In the demanding landscape of modern industry, efficient material handling is paramount to operational success, and the unsung heroes of this efficiency are undoubtedly conveyor belt rollers. These critical components are the backbone of any conveyor system, facilitating smooth, reliable, and continuous movement of goods and materials across various sectors. As global supply chains become more complex and production demands intensify, the need for high-performance, durable, and precisely engineered conveyor belt rollers for sale has never been more pressing. Industry trends indicate a significant shift towards more specialized materials, such as stainless steel, due to their superior resistance to corrosion, abrasion, and extreme temperatures, crucial for maintaining long-term system integrity and reducing downtime. The market is increasingly seeking solutions that offer not only robust mechanical properties but also energy efficiency and minimal maintenance requirements. This evolution is driven by stringent environmental regulations, rising energy costs, and the relentless pursuit of operational excellence. Businesses across petrochemical, mining, manufacturing, food processing, and wastewater treatment are constantly evaluating their infrastructure to enhance throughput and reduce total cost of ownership, making the selection of appropriate roller technology a strategic decision. Understanding the technical nuances, application-specific advantages, and the intricate manufacturing processes behind these rollers is vital for B2B decision-makers and technical personnel aiming to optimize their material handling operations and achieve sustainable growth in a competitive global market.

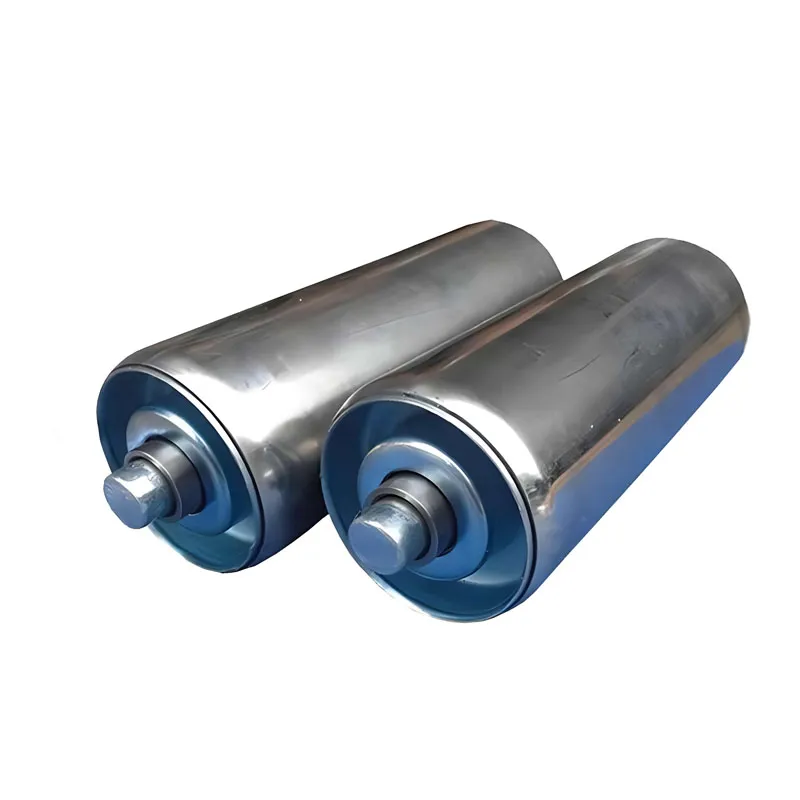

Precision Engineering: The Manufacturing Journey of Stainless Steel Conveyor Rollers

The production of high-quality stainless steel conveyor rollers involves a meticulous multi-stage manufacturing process, emphasizing precision, durability, and adherence to international standards. This journey typically begins with the selection of premium-grade raw materials, primarily stainless steel alloys such as AISI 304 or 316, chosen for their exceptional corrosion resistance, mechanical strength, and hygienic properties, making them ideal for challenging environments. The initial phase often involves precision cutting of steel tubing to the required roller length, followed by advanced forming techniques like cold rolling or drawing to achieve precise dimensional accuracy and superior surface finish. For critical components like shafts and bearing housings, processes such as forging or casting might be employed to ensure optimal structural integrity and load-bearing capacity. Following these preliminary steps, the components undergo sophisticated CNC machining (Computer Numerical Control) for precise drilling, turning, and milling, ensuring the exact fit for bearings, seals, and end caps. This stage is crucial for achieving minimal run-out and maximizing rotational stability, which directly impacts the lifespan and efficiency of the overall conveyor system. Post-machining, surfaces are meticulously polished or passivated to enhance corrosion resistance and reduce material adhesion, particularly important in food processing or pharmaceutical applications. Throughout the manufacturing cycle, rigorous quality control checks are implemented, adhering to standards such as ISO 9001 for quality management and ANSI/CEMA for conveyor equipment. These inspections cover dimensional accuracy, material composition verification, surface integrity, welding quality (if applicable), and dynamic balancing to ensure smooth operation. Rollers are also tested for static and dynamic load capacity, bearing life, and seal effectiveness to guarantee performance under specified operational conditions. This comprehensive manufacturing approach ensures that the resulting Stainless Steel Conveyor Roller products offer exceptional longevity, minimal maintenance, and optimal performance, providing significant advantages in terms of energy efficiency and operational reliability compared to traditional materials. This detailed process guarantees that customers investing in these advanced conveyor belt rollers for sale receive components engineered for enduring success in diverse and demanding industrial applications.

Technical Specifications & Performance Benchmarks

Selecting the appropriate conveyor rollers for sale requires a deep understanding of their technical parameters and how they align with specific operational demands. Key specifications include roller diameter, shell thickness, shaft diameter, bearing type, and sealing arrangements, all of which directly influence the roller's load capacity, rotational friction, and overall lifespan. For instance, larger roller diameters typically reduce belt sag and friction, leading to energy savings and extended belt life, while thicker shells provide enhanced durability against impact and abrasion. Bearing types, such as deep groove ball bearings or spherical roller bearings, are chosen based on the radial and axial loads anticipated, with precision bearings contributing significantly to lower friction and reduced power consumption. Advanced labyrinth seals or multi-lip seals are critical for protecting internal components from dust, moisture, and corrosive substances, thereby extending the service life, especially in harsh industrial environments. Our Stainless Steel Conveyor Rollers typically feature precision-machined shafts with tight tolerances, ensuring minimal vibration and noise during operation, which translates to a more stable and efficient conveying system. Furthermore, understanding the material grade of stainless steel, such as 304 for general corrosion resistance or 316 for enhanced resistance to chlorides and acids, is crucial for applications in chemical processing or marine environments. The static and dynamic balance of the rollers is also a critical parameter, with dynamic balancing reducing vibrational stress on the conveyor frame and associated machinery, thereby minimizing wear and tear on other system components. Manufacturers adhering to international standards like DIN, CEMA, or JIS provide assurance of consistent quality and interoperability. When considering conveyor belt rollers for sale, evaluating these technical specifications against your specific load, speed, and environmental conditions is paramount to achieving optimal system performance and long-term cost-effectiveness. Below is a representative table of common parameters for industrial conveyor rollers.

Typical Conveyor Roller Specifications

| Parameter | Stainless Steel Roller (Typical) | Standard Carbon Steel Roller (Comparison) |

|---|---|---|

| Material Grade | AISI 304 / 316 | Q235 / A36 |

| Shell Diameter (mm) | 60 - 219 (Customizable) | 60 - 219 (Customizable) |

| Shell Thickness (mm) | 3.0 - 10.0 | 3.0 - 8.0 |

| Shaft Diameter (mm) | 20 - 50 | 20 - 50 |

| Bearing Type | 6204/6205/6305/6306/6308 ZZ/2RS (Precision) | 6204/6205/6305/6306 ZZ/2RS (Standard) |

| Sealing System | Multi-lip labyrinth seal (IP65/IP66) | Standard labyrinth seal (IP54/IP55) |

| Corrosion Resistance | Excellent (Ideal for wet, corrosive environments) | Good (Requires coating/painting) |

| Operating Temperature | -20°C to +120°C | -10°C to +80°C |

| Service Life (Estimated) | >50,000 working hours (with proper maintenance) | 20,000 - 40,000 working hours (with proper maintenance) |

Diverse Applications & Unparalleled Advantages

The versatility of high-quality steel conveyor rollers for sale extends across a vast array of industries, each benefiting from their robust performance and specialized characteristics. In the petrochemical sector, for instance, these rollers are indispensable for conveying corrosive and abrasive materials, where their superior anti-corrosion properties prevent premature wear and ensure operational safety. Their non-sparking potential with certain alloys also adds a layer of safety in volatile environments. Similarly, in the metallurgy industry, including steel mills and foundries, rollers must withstand extreme temperatures and heavy loads; specialized heat-treated steel rollers or those with high-temperature lubricants are crucial for sustained performance. For the demanding bulk material handling applications in mining and quarrying, rollers designed for high impact and heavy abrasive loads are essential to ensure continuous operation and minimize downtime. The food processing and pharmaceutical industries rely heavily on stainless steel rollers due to their hygienic properties, ease of cleaning, and resistance to chemical sanitizers, which are critical for preventing contamination and adhering to stringent FDA and GMP regulations. In wastewater treatment plants, where exposure to aggressive chemicals and constant moisture is common, stainless steel conveyor rollers for sale offer unparalleled longevity and reliability. The inherent advantages of our Stainless Steel Conveyor Rollers, such as their low coefficient of friction, lead to significant energy savings by reducing the power required to drive the conveyor belt. Their exceptional anti-corrosion capabilities drastically extend service life in challenging environments, minimizing the need for frequent replacements and reducing maintenance costs. Furthermore, their precise manufacturing results in reduced noise levels and vibration, contributing to a safer and more comfortable working environment, while also prolonging the life of other conveyor system components. These combined benefits underscore why our specialized conveyor rollers are a preferred choice for industries seeking to enhance efficiency, reduce operational expenditures, and ensure long-term reliability in their material handling operations.

Choosing the Right Partner: Manufacturer Comparison and Custom Solutions

When evaluating suppliers for conveyor rollers for sale, B2B decision-makers must look beyond just price and consider a holistic set of criteria to ensure long-term value and reliability. A reputable manufacturer distinguishes itself through proven expertise, adherence to stringent quality standards, and a robust capacity for innovation and customization. Key factors for comparison include the manufacturer’s service tenure in the industry, which often reflects accumulated knowledge and refined processes, along with their portfolio of industry certifications such as ISO 9001 for quality management, CE marking for European safety standards, and potentially industry-specific certifications like FDA compliance for food-grade components. Furthermore, the manufacturer's R&D capabilities are crucial, as continuous improvement in material science, bearing technology, and sealing designs directly impacts roller performance and longevity. Companies offering advanced testing facilities, including dynamic load testing, wear resistance tests, and environmental chamber testing, provide an added layer of assurance. Our company, with over 20 years of dedicated service in conveyor system components, holds multiple international certifications and collaborates closely with leading research institutions to push the boundaries of roller technology. We pride ourselves on offering comprehensive custom solutions, recognizing that off-the-shelf conveyor belt rollers for sale may not always perfectly fit unique operational challenges. Our engineering team works in close consultation with clients to design and manufacture rollers tailored to specific dimensions, load capacities, environmental conditions (e.g., extreme temperatures, high humidity, corrosive atmospheres), and material handling requirements. This includes selecting appropriate stainless steel grades, optimizing shaft and shell thicknesses, specifying specialized bearings and sealing systems for dust, water, or chemical ingress protection, and applying specific surface treatments for enhanced wear or adhesion resistance. This bespoke approach ensures that clients receive not just a product, but a precisely engineered solution that integrates seamlessly into their existing infrastructure, maximizing operational efficiency and reducing unforeseen maintenance costs over the entire lifecycle of the conveyor system.

Real-World Impact: Case Studies and Client Success

The tangible benefits of investing in high-quality conveyor components are best demonstrated through real-world application cases and positive customer feedback. For example, a major chemical processing plant in the Gulf Coast region faced persistent issues with premature roller corrosion and bearing failures due to exposure to aggressive acids and high humidity, leading to significant unscheduled downtime and soaring replacement costs. After a detailed site assessment, our engineers recommended replacing their existing rollers with our specialized AISI 316 Stainless Steel Conveyor Rollers, featuring enhanced sealing systems and ceramic bearings. Post-installation, the plant reported a staggering 70% reduction in roller-related downtime within the first year, alongside a projected 40% decrease in maintenance expenditures over five years. This demonstrates the critical role of material science and precision engineering when choosing conveyor belt rollers for sale. Another notable case involves a large-scale mining operation in Western Australia, where conventional carbon steel rollers were failing rapidly under extreme abrasive conditions and heavy impact loads, resulting in frequent breakdowns of the primary ore conveying line. Our solution involved supplying heavy-duty steel conveyor rollers for sale with reinforced shells, extra-large shaft diameters, and specifically designed impact idlers. The robust design and superior materials extended the roller lifespan by over 150%, significantly improving operational uptime and contributing to a 10% increase in daily ore throughput by reducing bottlenecks. Customer testimonials consistently highlight improved system reliability, reduced energy consumption, and lower long-term operational costs as primary benefits. A recent client survey indicated that 95% of our customers would recommend our Stainless Steel Conveyor Rollers, citing their exceptional durability and performance in challenging environments. These success stories underscore our commitment to providing not just products, but comprehensive material handling solutions that deliver measurable value and contribute directly to our clients' operational efficiency and profitability. Our long-standing partnerships with industry leaders across various sectors further validate our position as a trusted provider of industrial conveyor solutions.

Frequently Asked Questions (FAQ) about Conveyor Rollers

-

Q: What makes stainless steel rollers a better investment than carbon steel?

Stainless steel rollers offer superior corrosion resistance, particularly in wet, acidic, alkaline, or high-humidity environments, significantly extending their service life compared to carbon steel, which is prone to rust and requires frequent protective coatings. While the initial cost of stainless steel conveyor rollers for sale might be higher, their lower maintenance requirements and longer lifespan result in a lower total cost of ownership (TCO) over time. They are also ideal for hygienic applications where cleanliness and contamination prevention are paramount, such as in food, pharmaceutical, and chemical industries. Carbon steel rollers, however, are a cost-effective solution for dry, less corrosive environments where budget is a primary concern and regular maintenance is feasible.

-

Q: How do you ensure the longevity and reliability of your conveyor rollers?

Our commitment to longevity and reliability starts with premium material selection (e.g., AISI 304/316 stainless steel, high-grade bearings). We employ advanced manufacturing processes, including precision CNC machining for tight tolerances and consistent quality, and robust welding techniques where applicable. Each roller undergoes rigorous multi-stage quality control, including dimensional checks, dynamic balancing tests, and sealed bearing integrity inspections. We also integrate advanced sealing systems (e.g., multi-lip labyrinth seals with IP65/IP66 ratings) to protect internal components from dust and moisture. Furthermore, our designs are optimized to reduce rotational friction, contributing to energy efficiency and extended bearing life. This comprehensive approach ensures that our conveyor rollers for sale perform reliably under demanding industrial conditions.

-

Q: What is the typical delivery schedule for custom conveyor rollers?

The delivery schedule for custom conveyor belt rollers for sale varies depending on the complexity of the design, the volume of the order, and the availability of specialized materials. For standard stainless steel conveyor rollers, lead times typically range from 3-4 weeks from order confirmation. For highly customized designs requiring specific material grades, unique dimensions, or specialized treatments, the lead time may extend to 6-8 weeks. We maintain transparent communication throughout the process, providing regular updates on manufacturing progress and shipping estimates. Our logistics team works diligently to ensure timely and efficient delivery worldwide, minimizing disruption to your operations. Expedited options may be available for urgent requirements, subject to project scope and material availability.

-

Q: What kind of warranty and customer support do you offer?

We stand behind the quality and performance of our Stainless Steel Conveyor Rollers with a comprehensive warranty. Typically, our products come with a 12-month warranty against manufacturing defects and material failures under normal operating conditions. Specific warranty terms may vary based on product type and application, and detailed warranty information is provided with each quotation. Beyond the warranty period, we offer robust after-sales customer support, including technical assistance, spare parts availability, and guidance on maintenance best practices. Our dedicated technical support team is available to address any operational questions or concerns, ensuring continuous optimal performance of your conveyor systems. We prioritize long-term client relationships and are committed to providing unparalleled service throughout the product lifecycle.

Authoritative References

- ISO 9001:2015 Quality Management Systems - Requirements. International Organization for Standardization.

- CEMA (Conveyor Equipment Manufacturers Association) Standard No. 502-2015, Belt Conveyors for Bulk Materials.

- ASTM A240/A240M-20: Standard Specification for Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip for Pressure Vessels and for General Applications.

- Bearing Technical Handbook: Selection, Installation, and Maintenance. SKF Publication.

- Journal of Material Processing Technology, Volume 209, Issue 10, May 2009, Pages 4867-4873.