In the rapidly evolving industrial landscape, efficient **conveyor for material handling** systems are pivotal for ensuring productivity, cost savings, and operational flexibility. This guide covers the latest industry trends, parametric comparisons, application scenarios, and cutting-edge innovations—highlighting the Six Nail Buckle solution for superior joint reliability.

1. Industry Trends in Conveyor for Material Handling

- Smart Automation: Utilization of IoT sensors, PLC controls, and MES integration is transforming traditional conveyor systems into smart, self-diagnosing networks. According to MarketsandMarkets, the global conveyor market is projected to reach $10.6 billion by 2027, with CAGR of 5.1%.

- Variable Speed Conveyor: Demand surges in industries needing real-time throughput adjustments (pharma, F&B, e-commerce), enhancing energy efficiency and process adaptability.

- Cleated Incline Conveyor: High adoption in industries with inclined transport where materials may slide back, such as mining and food processing.

- Sustainability & Cost Optimization: Energy-saving motors, modular belt designs, recyclable materials, and reduced maintenance demands are critical purchasing criteria.

- Stringent Compliance: Regulatory standards like ISO 9001, ANSI B20.1, FDA for food-grade belts, and safety shields are driving technical upgrades.

2. Key Technical Parameters for Conveyor for Material Handling

When selecting or engineering a conveyor for material handling system, several critical parameters should be rigorously evaluated:

| Parameter | Variable Speed Conveyor | Cleated Incline Conveyor | General Flat Belt Conveyor |

|---|---|---|---|

| Belt Material | PU, PVC, Rubber, Modular Plastic | PU, Heavy-Duty Rubber, Stainless Steel Mesh | PVC, PU, Steel Cord |

| Speed Range | 0.1–4 m/s (adjustable via VFD or servo) | 0.15–3 m/s (fixed or 2-step) | 0.2–3 m/s (fixed standard) |

| Load Capacity | 30–7,500 kg/h (application specific) | 20–5,000 kg/h | 25–6,000 kg/h |

| Incline Angle | Typically ≤ 10° | 15° – 45° (depends on cleat height) | ≤ 10° |

| Certification | ISO 9001, CE, UL, FDA if F&B | ISO 9001, MSHA, FDA | ISO, CE, ANSI |

| Typical Application | Assembly lines, logistics, pharma | Mining, food lifting, agriculture | Warehousing, bulk transfer |

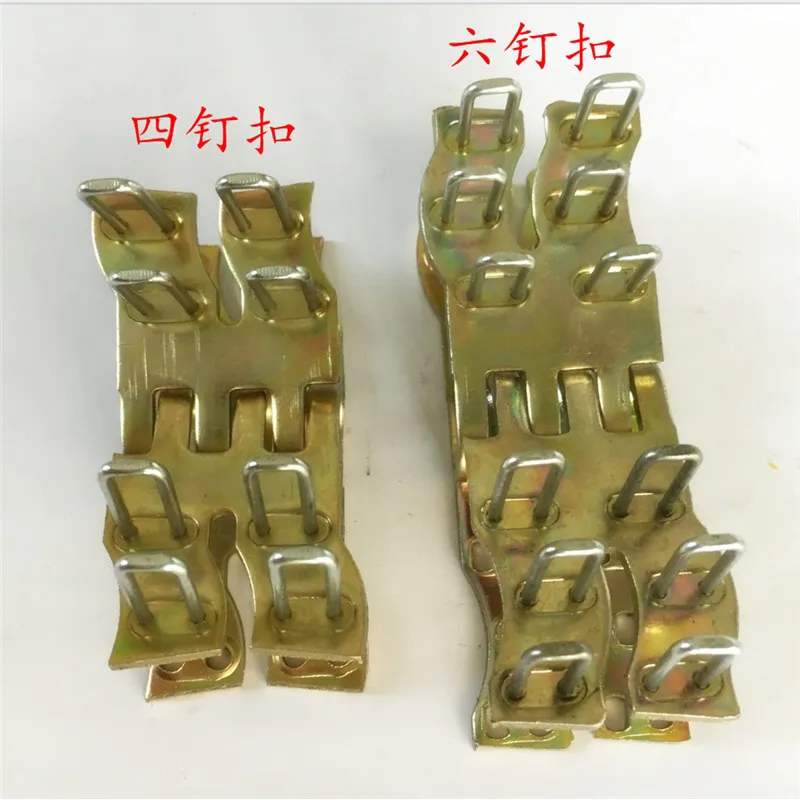

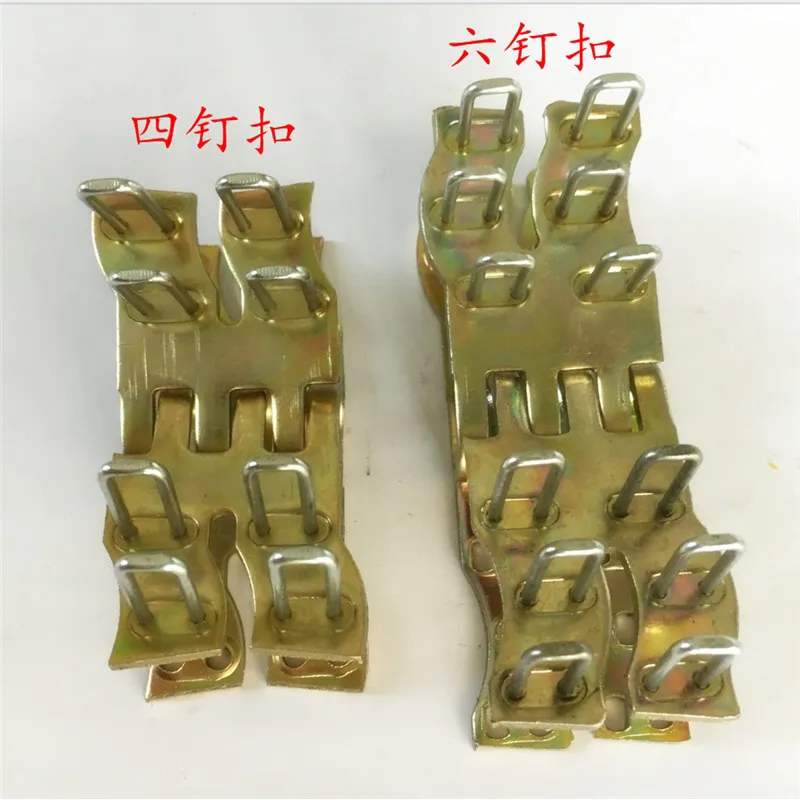

3. Six Nail Buckle: Product Deep Dive

Raw Material (AISI 304/316 Stainless Steel)

CNC Milling/Forming & Heat Treatment

Testing & QC

(ISO/ANSI Cert.)

Packing & Logistics

- Material: High grade AISI 304/316 Stainless Steel, ensuring strength, anti-corrosiveness, and longevity even under severe industrial conditions.

- Manufacture Process: Combination of precision casting, CNC machining for slot, hole, and taper formation, followed by controlled heat treatment for surface hardness & resilience.

- Testing Standards: Each buckle undergoes tensile strength test, microstructure check and is batch-certified with ISO 9001, ANSI B20.1.

- Application Industries: Oil & gas, mining, metallurgy, petrochemical transport, construction aggregate, food, and municipal water management.

- Performance Highlights:

- Available in section widths: 16, 22, 30, 38, 45, 56 mm

- Single buckle static loading up to 12,000N (Lab data)

- Corrosion resistance in 298hr salt-spray environment

- Engineered lifespan: ≥ 250,000 cycles (under ISO 4184)

Conclusion: The Six Nail Buckle is engineered to outperform standard fasteners, specifically for high-load, corrosive, and abrasive environments. Its multi-nail locking system reduces joint failure, minimizes downtime, and ensures conveyor belt integrity.

4. Manufacturer and Product Comparison Table

HG Conveyor Belt (Six Nail Buckle)

- Material: AISI 304/316 SS

- Slot Machining: CNC precision

- Cert: ISO 9001, ANSI

- Warranty: 18 months

Flexco

- Material: Carbon steel, SS

- Slot: Press-fit

- Cert: MSHA, UL

- Warranty: 12 months

Richwood

- Material: Stainless steel

- Slot: Die cut

- Cert: ISO

- Warranty: 12 months

Minet Lacing

- Material: Galvanized steel

- Slot: Press, manual

- Cert: CE

- Warranty: 12 months

| Criteria | Six Nail Buckle | Typical Competition |

|---|---|---|

| Static Strength (N) | 12,000 | 7,000 - 8,500 |

| Anti-Corrosion Grades | AISI 304/316 (Excellent) | Galvanized, Carbon (Good to Avg.) |

| Fit Precision | ±0.05mm (CNC machined) | ±0.21mm (Die/Manual) |

| Cycle Life | >250,000 cycles | <150,000 cycles |

| Custom Size Support | Yes (16–65mm width) | Limited |

| Testing Standard | ISO 4184, ANSI B20.1 | MSHA/ISO |

5. Customization & Engineering Support

For industry-specific challenges, HG Conveyor Belt offers complete customization services—tailored dimensions, alternative alloys for aggressiveness, and hybrid joint design. Support includes:

- On-site measurement and audits

- Rapid prototyping via CNC/3D

- Integration with variable speed conveyors & cleated incline conveyor platforms

- Full documentation: 2D/3D CAD, installation/maintenance guides

6. Application Cases & Customer Experiences

— Plant Engineer, Metallurgical Processing, South China

- Oil & Gas Drilling Platforms: Six Nail Buckle survived high salinity and heat, maintaining conveyor belt connection integrity for 22 months (vs. 9–11 months for legacy fasteners).

- Aggregate/Mining: Handles 240 t/hr crushed stone, no fastener shearing or slippage over an 18-month period.

- Municipal Water Treatment: Stainless variant meets ANSI/NSF 61 requirements, certified via third-party lab.

- Food Industry: PU belts joined with Six Nail Buckle successfully underwent FDA-compliant sanitation tests.

7. Delivery, QA & Customer Support

- Delivery Lead Time: Standard shipment: 7–10 working days. Custom: 17–22 working days.

- Warranty: 18 months replacement guarantee (excluding misuse damage).

- Support: 24/7 technical hotline, on-site installation, remote engineering consultation.

- Certifications: ISO 9001, ANSI B20.1, with batch CoC and test documentation supplied.

- References: Cooperating with >70 manufacturing enterprises globally.

8. FAQ: Professional Terminology & Technical Clarification

-

Q1: What is the significance of 'variable speed conveyor' in material handling?

Variable speed conveyors enable precise flow control via VFDs (Variable Frequency Drives), optimizing throughput, reducing energy usage, and accommodating varying process requirements. Ideal for multi-product lines and adjustable logistics centers.

-

Q2: How does cleated incline conveyor differ from standard flat belt?

A cleated incline conveyor features raised cleats/baffles on the belt, preventing rollback of materials on steep gradients (15°–45°), key in granular, food, and mining transport.

-

Q3: What’s the role of Six Nail Buckle material AISI 304/316?

AISI 304/316 stainless steel provides excellent anti-corrosion and mechanical strength, passing salt-spray (ASTM B117) and ISO 15156 compliance, thus suitable for harsh industrial and marine applications.

-

Q4: Which installation standards apply to conveyor belt fasteners?

ANSI B20.1 and ISO 9001 are primary. For food-grade, FDA 21 CFR 177.2600 compliance is also recommended.

-

Q5: Does Six Nail Buckle compatibility extend to variable speed conveyor systems?

Yes—its robust design and fatigue resistance make it fully compatible with rapid accelerations/decelerations and flexible conveyor speeds, crucial for automation lines.

-

Q6: Can Six Nail Buckle support customized sizes/widths?

Absolutely. Widths from 16–65mm, slot and pitch can be custom-machined within ±0.05mm tolerances per CAD/2D drawings.

-

Q7: What does expected service life mean in ISO 4184 context?

It signifies durability under cyclic loading (tension/flexion) as per ISO standards, with the Six Nail Buckle rated for ≥250,000 full duty cycles without failure.

9. Why Choose Six Nail Buckle for Your Conveyor for Material Handling?

- Proven Longevity: Extended service life and superior integrity vs. conventional fasteners.

- Certified Quality: Every batch tested, certified, and traceable against ISO/ANSI standards.

- Cross-Industry Versatility: Suitable for variable speed conveyor, cleated incline conveyor, and more.

- Custom Engineering & Responsive Support: Co-engineering and technical hotline without extra charges.

- Data-Backed Decisions: Technical specifications and case histories published for transparency.

10. References & Further Reading

- Latest Developments in Conveyor Fastening – ConveyorBeltForum

- A Review on Innovative Designs for Conveyors in Material Handling – Journal of Cleaner Production

- ISO 9001:2015 – Quality Management Systems Requirements

- ANSI B20.1 - Conveyor and Related Equipment Standards

- Conveyor Speed Control Trends – Flexco Industry News