Low Temperature Resistant Conveyor Belt: Engineering Excellence for Harsh Climates

Explore the cutting-edge technology behind cold-resistant conveyor belts designed by Hebei Roule Transport Machinery Manufacturing Co., Ltd.

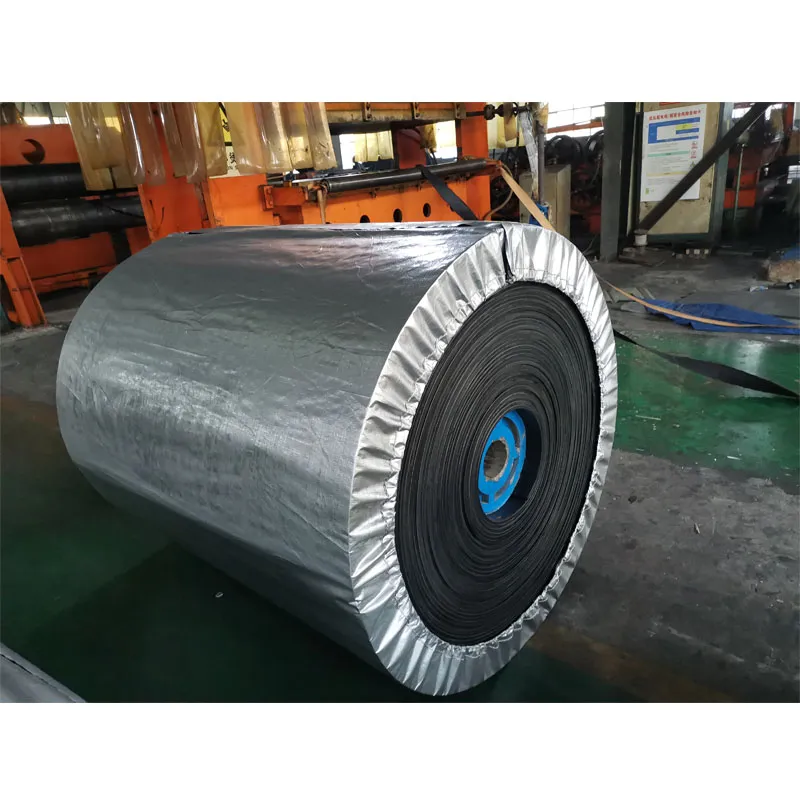

Introduction to Cold-Resistant Conveyor Belts

In the realm of industrial material handling, conveyor belts must adapt to extreme conditions. Hebei Roule Transport Machinery Manufacturing Co., Ltd. has pioneered low temperature resistant conveyor belts that thrive in sub-zero environments. These belts combine advanced materials and engineering to ensure reliability in temperatures as low as -60°C.

Product Overview

Hebei Roule's cold-resistant conveyor belts are engineered for durability and performance in extreme cold. Key features include:

- Material Composition: Utilizes NN100–NN350 and EP100–EP350 materials for optimal flexibility and strength.

- Customizable Dimensions: Belt widths range from 500mm to 2000mm, with options for custom sizes.

- Multi-Layer Fabric Construction: 1–10 layers of fabric for enhanced load-bearing capacity.

Technical Specifications

| Parameter | Details |

|---|---|

| Material | NN100–NN350, EP100–EP350 |

| Belt Width | 500mm–2000mm (customizable) |

| Fabric Layers | 1–10 layers |

| Cold Resistance | C1: -45°C to 50°C; C2: -60°C to -50°C |

| Performance Classification | H (scratch-resistant), D (wear-resistant), L (general) |

Key Advantages

1. Exceptional Cold Resistance

These belts operate reliably in environments as cold as -60°C, making them ideal for Arctic regions or refrigerated facilities. The combination of natural rubber and butadiene rubber ensures flexibility and impact resistance even in extreme cold.

2. High Load-Bearing Capacity

Engineered with reinforced fabric layers, these belts maintain structural integrity under heavy loads. This makes them suitable for transporting bulk materials like coal, ore, and grain.

3. Superior Wear and Corrosion Resistance

The specialized rubber compound resists abrasion and chemical degradation, extending the belt's lifespan. This is critical in environments where exposure to poultry manure or industrial chemicals is common.

Applications and Industry Use Cases

Hebei Roule's cold-resistant conveyor belts are widely used in:

- Outdoor Operations: Mining, construction, and logistics in cold climates.

- Refrigerated Warehouses: Transporting frozen goods in cold storage facilities.

- Industrial Facilities: Handling materials in environments with extreme temperature fluctuations.

For specialized applications like conveyor belt for concrete, these belts offer unmatched durability and performance.

Company Background

Hebei Roule Transport Machinery Manufacturing Co., Ltd. is a leading manufacturer of conveyor belts and related equipment. With a focus on innovation and quality, the company has established itself as a trusted provider in the industrial sector. Their commitment to cold-resistant materials aligns with global standards for reliability and performance.

Ensuring Reliability: NIST Standards and Beyond

While the National Institute of Standards and Technology (NIST) does not directly regulate conveyor belts, its guidelines on material performance under extreme conditions provide a framework for evaluating cold-resistant materials. According to NIST research, materials must maintain mechanical integrity and flexibility at low temperatures to avoid failure in operational environments (NIST, 2023). Hebei Roule's belts exceed these benchmarks, ensuring compliance with international standards for cold-weather applications.

Reference: NIST Standards for Material Performance

Conclusion

Hebei Roule Transport Machinery Manufacturing Co., Ltd.'s low temperature resistant conveyor belts represent a significant advancement in industrial material handling. With their ability to withstand extreme cold, high load capacity, and resistance to wear, these belts are indispensable for operations in harsh environments. For more information, visit the product page or explore the company website.