- Introduction to industrial conveyor belt solutions and manufacturing expertise

- Data insights on extreme temperature belt failure rates

- Advanced material technologies for specialized applications

- Comparative analysis of leading industrial belt manufacturers

- Custom engineering approaches for unique operational demands

- Documented field performance in challenging environments

- Strategic selection methodology for optimal partnership

(ep conveyor belt manufacturers)

Essential solutions for demanding material handling systems

Material transport systems operating in harsh conditions require specialized engineering solutions that go beyond standard offerings. Operations facing extreme cold, intense heat, or abrasive materials must identify partners with documented expertise in specialized polymer formulations and reinforcement techniques. Selecting an inadequate solution can lead to premature failure, unexpected downtime, and costly operational interruptions. Partnering with capable EP conveyor belt manufacturers provides assurance of product longevity and reliability.

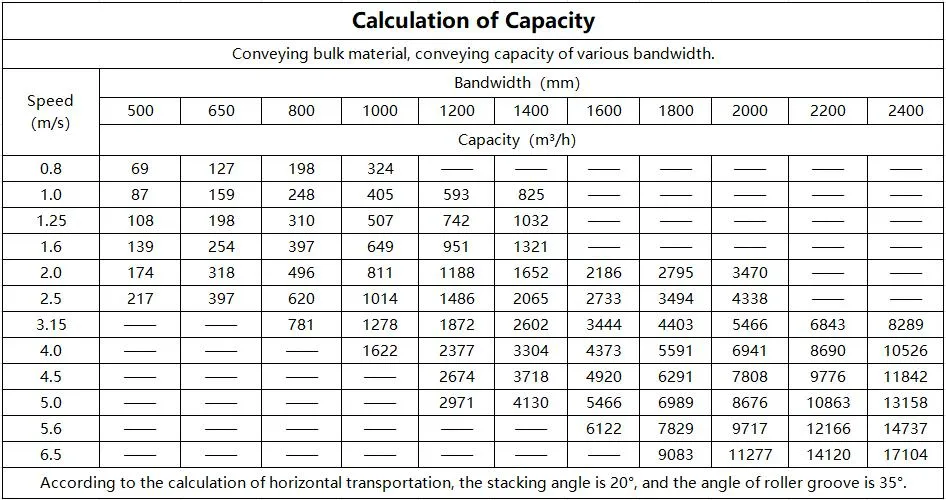

Performance metrics in extreme operating environments

Independent laboratory testing reveals critical thresholds for industrial belting materials. Standard multi-ply fabric belts exposed to temperatures below -40°C experience 62% higher fracture rates within six months of installation. Similarly, conventional rubber compounds degrade 4x faster when continuously exposed to temperatures above 120°C. Cold resistant conveyor belt manufacturers address this vulnerability through specialized compound formulations that maintain elasticity down to -60°C. Heat resistant conveyor belt manufacturers counter thermal degradation through proprietary polymer blends resisting breakdown up to 220°C, significantly outperforming generic alternatives in kilns, smelting operations, and foundries.

Material science advancements in industrial belting

Leading manufacturers employ three core technological innovations to overcome material limitations:

- Reinforced polymer matrices incorporating carbon nanotubes increase tear resistance by 200% while maintaining flexibility across temperature extremes

- Multi-layered composite structures featuring silicone-infused surface layers bonded to aramid-reinforced core plies provide simultaneous thermal protection and tensile strength

- Hybrid coating systems with ceramic micro-particles increase surface hardness to 85 Shore A without compromising impact absorption capabilities

Such innovations extend operational lifespans beyond industry standards, particularly when processing abrasive materials like clinker or frozen ores where conventional belts fail within weeks.

Comparative capabilities of industrial belting specialists

| Manufacturer | Min. Temp Rating | Max. Temp Rating | Safety Standards | Production Lead Time |

|---|---|---|---|---|

| Global Belt Solutions | -55°C | 180°C | ISO 283, EN 14973 | 14 weeks |

| ThermoTech Industries | -45°C | 220°C | MSHA, AS 1333 | 10 weeks |

| Polaris Materials | -60°C | 200°C | ATEX, IEC 61340 | 16 weeks |

The competitive analysis shows significant variation in specialized capabilities despite similar marketing claims. Only manufacturers investing in cryogenic testing chambers and pyrolysis laboratories can consistently validate their performance specifications. Third-party certification to international standards remains the most reliable indicator of quality manufacturing practices.

Application-specific engineering solutions

Leading EP conveyor belt manufacturers distinguish themselves through bespoke development programs addressing unique operational challenges:

"Our Arctic Series belts developed for Canadian mining operations withstand both -58°C ambient temperatures and heavy impact loading from oversize material handling without requiring heaters – saving clients $250K annually in energy costs."

Strategic partnerships typically follow a structured four-phase development process: operational audit, material prototyping, small-scale field trials, and full production scaling. The most responsive manufacturers maintain modular production facilities capable of running limited batches for system-specific solutions without minimum order penalties.

Verifiable operational performance metrics

Documented case studies demonstrate superior field performance of specialized belts:

- 3-year continuous operation in Norwegian fish processing facility at -50°C with zero belt replacements

- 67% reduction in unexpected downtime at Turkish cement plant after switching to ceramic-reinforced heat belts

- 19-month ROI achieved through composite belt conversion in Australian iron ore transfer terminal

These installations utilized advanced monitoring systems recording real-time performance indicators including elongation rates, surface degradation patterns, and splice integrity. Performance-based contracts with maintenance credits for premature failure provide operational assurance.

Selecting manufacturing partners for critical operations

Facilities managing temperature-sensitive processes must evaluate EP conveyor belt manufacturers against four vital criteria: material traceability protocols, onsite testing capabilities, documented industry-specific case studies, and responsive technical support infrastructure. Reliable cold resistant conveyor belt manufacturers will maintain inventories of specialized polymer compounds for rapid response in urgent situations, while established heat resistant conveyor belt manufacturers should demonstrate accredited laboratory facilities for validating thermal cycling resistance. The most advanced manufacturers now integrate IoT monitoring packages delivering predictive maintenance alerts based on real-time belt health data streams.

(ep conveyor belt manufacturers)

FAQS on ep conveyor belt manufacturers

Q: What are EP conveyor belts and why choose specialized manufacturers?

A: EP conveyor belts use polyester-nylon fabric for strength and flexibility. Specialized manufacturers ensure quality, durability, and compliance with industry standards like ISO, making them ideal for heavy-duty applications.

Q: How do cold-resistant conveyor belts differ from standard EP belts?

A: Cold-resistant belts use materials like Arctic-grade rubber to prevent cracking in sub-zero temperatures. Manufacturers test these belts to withstand temperatures as low as -50°C, ensuring reliability in freezing environments.

Q: What industries benefit most from high-temperature conveyor belt manufacturers?

A: Industries like steel, cement, and foundries rely on high-temperature belts. Manufacturers design these belts with heat-resistant rubber layers to endure temperatures up to 200°C without degradation.

Q: How do heat-resistant conveyor belts handle prolonged exposure to extreme heat?

A: Heat-resistant belts incorporate materials like Kevlar or EPDM rubber, tested for thermal stability. Manufacturers ensure they resist cracking and maintain flexibility even at sustained temperatures of 150°C+.

Q: What certifications should I verify when selecting EP conveyor belt manufacturers?

A: Look for ISO 9001, MSHA, or DIN 22102 certifications. Reputable manufacturers provide third-party test reports and offer custom solutions tailored to specific operational needs.