In conveyor systems, the carry roller plays a crucial role in supporting and guiding the conveyor belt and the material it carries. Designed to minimize friction and wear, the carry roller ensures smooth and efficient material transport, reducing operational downtime.

High-quality carry rollers help maintain proper belt alignment, preventing slippage and damage. Their durable construction is essential for handling heavy loads and harsh industrial environments, including mining, quarrying, and bulk material handling.

When selecting a carry roller, it’s important to consider factors such as material composition, bearing type, and sealing mechanisms. Robust rollers with high-grade bearings and effective seals resist contamination and prolong service life, reducing maintenance costs.

An efficient carry roller not only enhances conveyor reliability but also contributes to energy savings by reducing resistance on the belt system. This makes investing in superior rollers a cost-effective choice for long-term conveyor operation.

The Role of a Reliable Troughing Idlers Manufacturer in Conveyor Systems

A professional troughing idlers manufacturer is key to ensuring the availability of reliable and customized conveyor components. The troughing idlers manufacturer designs and produces the rollers that shape the conveyor belt into a trough, optimizing load carrying capacity and material control.

Choosing an experienced troughing idlers manufacturer guarantees access to products that meet industry standards for durability, precision, and performance. Such manufacturers employ advanced materials and manufacturing processes to deliver components capable of withstanding heavy impacts, abrasive materials, and extreme environmental conditions.

Collaboration with a trusted troughing idlers manufacturer also means tailored solutions for specific conveyor configurations, enhancing system efficiency and reducing operational wear.

With a reputable troughing idlers manufacturer, businesses gain a partner dedicated to quality, innovation, and timely delivery—ensuring conveyors run smoothly and maintenance intervals extend.

Why Troughing Rollers are Essential for Optimal Material Handling

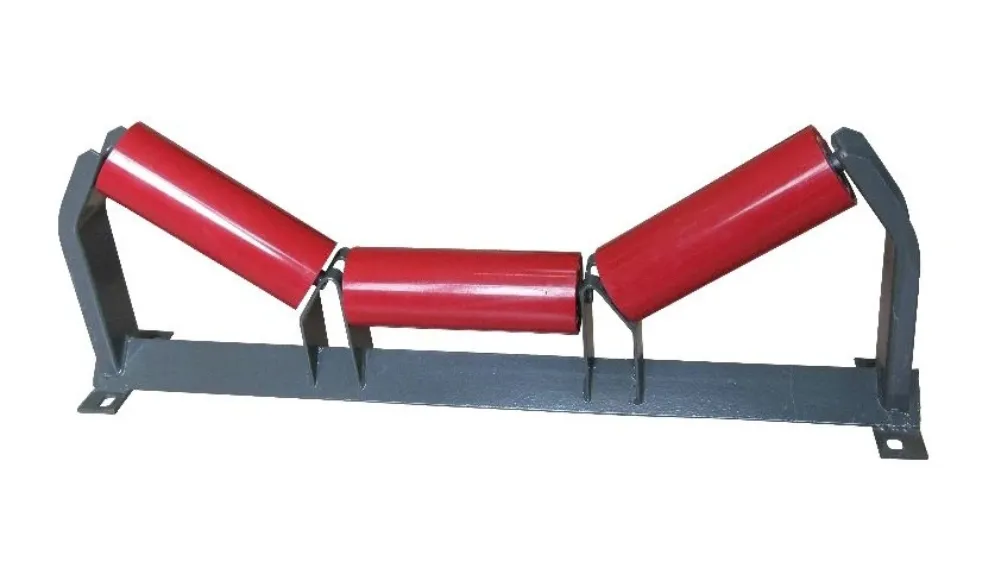

The troughing roller is a specialized roller designed to support the conveyor belt edges, shaping the belt into a trough to keep bulk materials centered during transport. This reduces spillage and increases conveyor capacity.

Selecting the right troughing roller is critical. It must be durable enough to resist abrasion and impact from heavy, sharp materials while maintaining smooth rotation to minimize belt wear.

Modern troughing rollers feature high-quality steel construction, precision bearings, and weather-resistant seals. These features protect the roller from dust, moisture, and corrosion, enabling long-lasting performance even in tough environments.

Properly installed troughing rollers improve conveyor belt tracking and reduce operational noise, further enhancing the working environment and overall system reliability.

Innovations from Leading Troughing Idlers Manufacturers

Top troughing idlers manufacturers continually innovate to improve roller design and manufacturing techniques. Advances include the use of composite materials to reduce weight without sacrificing strength and coatings that increase resistance to wear and corrosion.

Improved sealing systems developed by troughing idlers manufacturers extend bearing life by effectively blocking contaminants, which is crucial in dusty or wet conditions.

Many leading troughing idlers manufacturers also focus on modular designs, making it easier to replace individual components and reduce downtime during maintenance.

Enhanced quality control and testing by troughing idlers manufacturers ensure each roller meets stringent performance standards, guaranteeing reliable operation in various industries such as mining, cement, and power generation.

Choosing the Right Carry Roller and Troughing Roller Supplier for Your Needs

Selecting a dependable supplier for carry rollers and troughing rollers requires careful evaluation of product quality, customization options, delivery reliability, and technical support.

A reputable troughing idlers manufacturer will offer a comprehensive range of rollers designed to fit different conveyor belt widths, loads, and operational environments.

Look for suppliers who provide detailed product specifications, material certifications, and installation guidance, ensuring you get rollers that match your system’s requirements precisely.

Strong after-sales service, including spare parts availability and maintenance advice, is another important factor when choosing your carry roller and troughing roller supplier.

Partnering with a trusted troughing idlers manufacturer guarantees that your conveyor system remains efficient, reducing downtime and lowering total operational costs.

carry roller FAQs

What is the function of a carry roller in conveyor systems?

The carry roller supports the conveyor belt and the material it carries, minimizing friction and ensuring smooth movement. It helps maintain belt alignment and reduces wear on both the belt and the conveyor structure.

How does a troughing idlers manufacturer ensure product quality?

A reliable troughing idlers manufacturer uses high-grade materials, precision manufacturing processes, and rigorous testing. Advanced sealing and bearing technology are applied to enhance durability and performance.

Why are troughing rollers important for material handling?

Troughing rollers shape the conveyor belt into a trough, which keeps bulk material centered and prevents spillage. This improves load capacity and conveyor efficiency.

What materials are commonly used for carry rollers and troughing rollers?

High-strength steel is typical for the roller body, with bearings made from alloy steel or stainless steel. Seals are often made from rubber or synthetic materials to protect internal components from contaminants.

How to choose the right troughing idlers manufacturer?

Look for manufacturers with proven experience, quality certifications, customizable product ranges, and strong customer support. Their ability to deliver on time and provide technical guidance is also crucial.