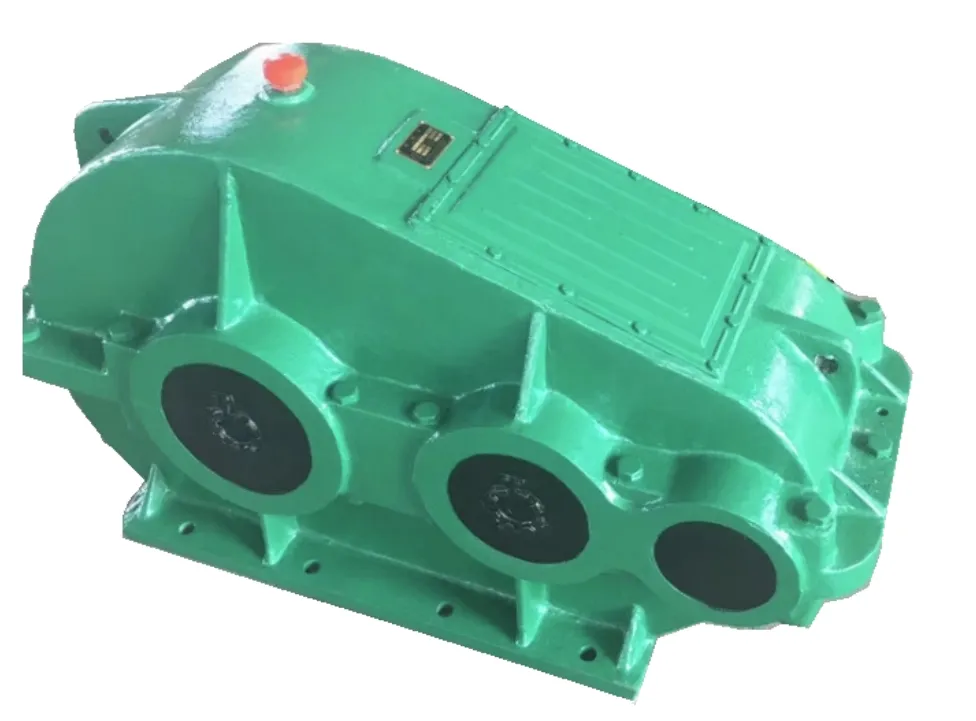

The conveyor gearbox is a vital component in material handling systems, responsible for transmitting power from the motor to the conveyor belt while adjusting speed and torque to match operational requirements. It acts as the mechanical link ensuring that the conveyor moves efficiently and reliably under varying load conditions.

Proper selection and maintenance of the conveyor gearbox can dramatically improve conveyor performance and lifespan. This component reduces the motor’s speed and increases torque, allowing the conveyor system to handle heavy loads without compromising speed or safety.

Industrial conveyors require gearboxes designed to withstand harsh environments, including dust, moisture, and temperature extremes. Hence, durability and precision engineering are essential features of a reliable conveyor gearbox.

Additionally, the conveyor gearbox must integrate seamlessly with the motor and drive system. Any mismatch can lead to excessive wear, noise, or failure, impacting production efficiency and maintenance costs.

Leading manufacturers emphasize advanced sealing, hardened gears, and high-quality bearings in their conveyor gearbox design to ensure robustness and low maintenance in demanding industrial environments.

Optimizing Conveyor Belt Motor and Gearbox Integration for Superior Performance

The synergy between the conveyor belt motor and gearbox is fundamental to achieving efficient, smooth, and reliable conveyor operation. Combining the motor and gearbox as a matched system enhances power transmission and reduces mechanical losses.

When designing or upgrading conveyor systems, engineers carefully select the conveyor belt motor and gearbox pair based on required torque, speed, load type, and environmental factors. This ensures optimal power delivery and extends the life of both components.

Advanced conveyor belt motor and gearbox assemblies now often come pre-integrated, simplifying installation and maintenance. These units can include features like modular mounts, sealed bearings, and lubrication systems, designed specifically for conveyor applications.

The integration of variable frequency drives (VFDs) with the motor and gearbox allows for precise speed control, enhancing conveyor efficiency and reducing energy consumption.

A well-matched conveyor belt motor and gearbox system minimizes mechanical stress, improves system responsiveness, and reduces downtime caused by failures or excessive wear.

Key Features and Benefits of Conveyor Motor Gearbox Solutions

The conveyor motor gearbox is engineered to handle the demanding conditions of conveyor systems. Key features of a high-quality conveyor motor gearbox include precision-machined gears for smooth operation, rugged housings for protection, and advanced sealing to prevent contamination.

Benefits of choosing the right conveyor motor gearbox include increased system reliability, reduced maintenance frequency, and improved energy efficiency. High-quality gearboxes ensure consistent torque output even under heavy or fluctuating loads.

Some models incorporate condition monitoring sensors within the conveyor motor gearbox to track temperature, vibration, and lubricant status, enabling predictive maintenance strategies.

The conveyor motor gearbox also plays a crucial role in noise reduction by ensuring gears mesh smoothly and operate quietly, which improves working conditions and complies with workplace regulations.

Selecting gearboxes with optimized conveyor gearbox design tailored to your conveyor’s unique needs helps maximize uptime and system productivity.

Innovations in Conveyor Gearbox Design for Modern Industry

Recent advances in conveyor gearbox design have focused on improving efficiency, durability, and ease of maintenance. Use of advanced materials such as hardened steel and lightweight alloys enhances strength while reducing weight.

Modular conveyor gearbox design allows for easier customization and upgrades, letting manufacturers tailor solutions to specific conveyor configurations and applications.

Sealing technologies have advanced to offer superior protection against dust, moisture, and corrosive agents, extending gearbox life and reducing downtime in harsh industrial environments.

Innovative lubrication systems incorporated into the conveyor gearbox design provide consistent lubrication without frequent maintenance, improving reliability and reducing operating costs.

Integration with smart sensors and IoT technology is becoming standard, enabling real-time monitoring of gearbox health, vibration, and temperature. This data-driven approach to maintenance enhances safety and lowers unexpected failures.

Selecting the Right Conveyor Gearbox for Your Application

Choosing the appropriate conveyor gearbox requires a thorough understanding of your conveyor system’s requirements including load capacity, speed, environment, and duty cycle. Over-sizing or under-sizing a gearbox can lead to inefficiency and premature wear.

Consulting with experienced suppliers ensures you get a conveyor gearbox that matches the motor output and conveyor load, providing balanced performance and longevity.

Considerations such as gear type (helical, worm, bevel), mounting orientation, and housing material affect the gearbox’s suitability for your specific application.

Incorporating the conveyor belt motor and gearbox as an integrated unit often simplifies installation and improves overall system efficiency.

Budget constraints must be balanced with quality and expected maintenance costs. While lower-cost gearboxes may save upfront, high-quality units with superior conveyor gearbox design often provide better ROI through durability and reduced downtime.

Investing time and resources into selecting the right conveyor gearbox protects your production lines, reduces maintenance headaches, and keeps your conveyor systems running smoothly.

conveyor gearbox FAQs

What is the function of a conveyor gearbox?

A conveyor gearbox transmits power from the motor to the conveyor, reducing speed and increasing torque to suit the conveyor’s operational requirements. It ensures the conveyor belt moves reliably under various loads while protecting the motor from overload.

How do conveyor belt motor and gearbox work together?

The motor generates rotational force, which the gearbox modifies by decreasing speed and increasing torque. This combination enables the conveyor belt to move smoothly and handle varying loads efficiently without stressing the motor or belt.

What are common types of conveyor gearboxes?

Common types include helical, worm, bevel, and planetary gearboxes. Each type offers different benefits: helical gearboxes are efficient and quiet, worm gearboxes provide high torque in a compact design, bevel gearboxes change shaft direction, and planetary gearboxes are compact with high torque capacity.

How does conveyor gearbox design impact system performance?

A well-engineered conveyor gearbox design ensures efficient power transmission, durability under harsh conditions, minimal noise, and ease of maintenance. Design factors like gear quality, sealing, lubrication, and material choice directly influence reliability and lifespan.

What should I consider when selecting a conveyor gearbox?

Consider the conveyor’s load capacity, speed, operating environment, duty cycle, gear type, mounting requirements, and budget. Matching the gearbox with the motor and conveyor ensures optimal performance and longevity. Consulting with suppliers helps make the best choice.