Ceramic Conveyor Drum: Enhancing Durability and Efficiency in Industrial Conveyors

Introduction

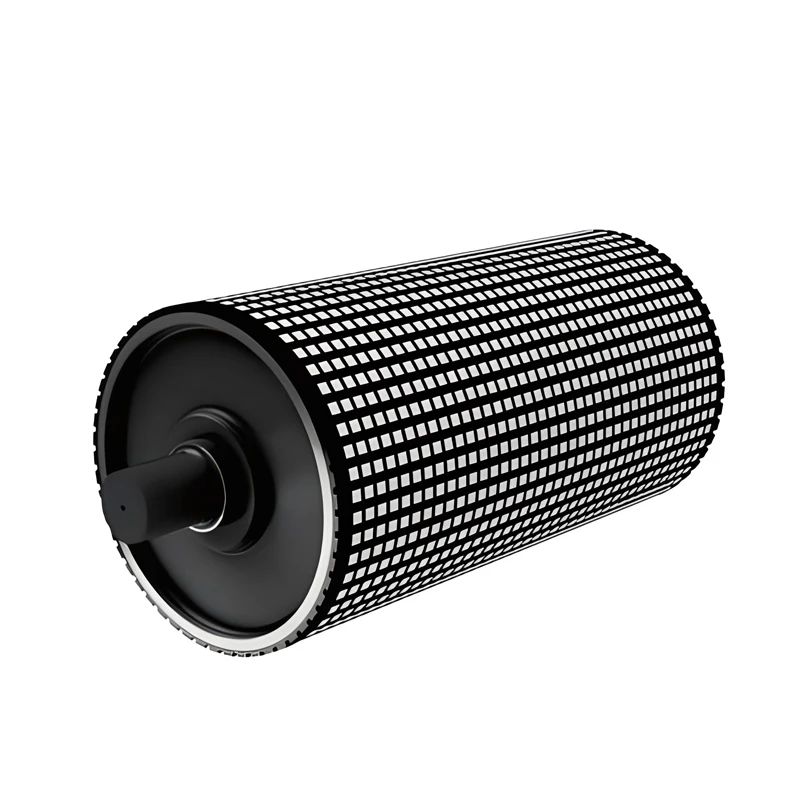

The Ceramic Conveyor Drum represents a significant advancement in material handling technology, designed to address the critical challenges of wear and friction in industrial conveyor systems. As a key component of belt conveyors, this drum combines the strengths of rubber and ceramic materials to create a surface that is both highly durable and effective in maintaining traction. Developed by Hebei Roule Transport Machinery Manufacturing Co., Ltd., a leading manufacturer in the field of industrial conveyor systems, the Ceramic Conveyor Drum is engineered to meet the demanding requirements of modern manufacturing and logistics environments.

Product Features and Advantages

The Ceramic Conveyor Drum is a specialized roller designed for belt conveyors, featuring a unique construction that enhances its performance and longevity. The drum consists of a metal-based cylinder, typically made of steel, which serves as the core structure. This metal base is then wrapped with a rubber cylinder, providing a flexible and impact-absorbing layer. The outer surface of the rubber cylinder is embedded with wear-resistant ceramic tiles, which are strategically placed to maximize friction and minimize wear.

One of the standout features of this drum is the granular protrusions on the ceramic tiles. These protrusions increase the surface roughness, thereby improving the friction between the drum and the conveyor belt. This design is particularly effective in environments where high levels of abrasion and heavy loads are common. The combination of rubber's toughness and ceramic's hardness ensures that the drum can withstand the harsh conditions typical of industrial applications.

The ceramic tiles themselves can be of regular or irregular shapes, allowing for customization based on specific application needs. Their placement on the rubber cylinder can be uniform or non-uniform, depending on the desired friction characteristics. This flexibility in design makes the Ceramic Conveyor Drum suitable for a wide range of industrial settings, from mining and construction to food processing and pharmaceuticals.

Technical Specifications

| Parameter | Details |

|---|---|

| Material Composition | Steel (core), Rubber (middle layer), Ceramic tiles (outer layer) |

| Surface Treatment | Ceramic tiles with granular protrusions for enhanced friction |

| Dimensions | Vary based on application; standard sizes available |

| Wear Resistance | High, due to ceramic's hardness and rubber's toughness |

| Friction Enhancement | Granular protrusions on ceramic tiles increase surface roughness |

| Manufacturing Process | Casting diamond-shaped rubber process and rubber/ceramic composite lining |

Manufacturing Processes

The Ceramic Conveyor Drum is produced using two primary manufacturing techniques: the casting diamond-shaped rubber process and the rubber/ceramic composite lining process. The casting diamond-shaped rubber process involves compounding a layer of wear-resistant rubber on the surface of the drum. This rubber layer is chosen for its high wear resistance and toughness, which help to protect the underlying steel structure from damage.

The second method, the rubber/ceramic composite lining process, involves applying a composite lining of rubber and ceramic to the drum's surface. This approach combines the wear resistance of ceramics with the flexibility and toughness of rubber, creating a surface that is both durable and effective in maintaining traction. Theoretical studies have shown that the elastic modulus of materials plays a significant role in their wear resistance, particularly in fatigue wear scenarios. By optimizing the material properties, the Ceramic Conveyor Drum ensures prolonged service life and reduced maintenance costs.

Applications in Industry

The Ceramic Conveyor Drum is widely used in various industrial applications where high wear resistance and efficient material handling are critical. In the mining industry, for example, conveyor systems are subjected to extreme conditions, including heavy loads and abrasive materials. The Ceramic Conveyor Drum's design ensures that it can withstand these challenges, reducing downtime and maintenance requirements.

In the construction sector, conveyor systems are often used to transport aggregates, cement, and other materials. The high friction provided by the ceramic tiles ensures that the conveyor belt remains in place, even under heavy loads. Similarly, in the food processing industry, where hygiene and durability are paramount, the Ceramic Conveyor Drum offers a reliable solution that meets stringent safety standards.

The pharmaceutical industry also benefits from the use of Ceramic Conveyor Drums. Here, the drums are employed to transport sensitive materials, where any contamination or wear could compromise product quality. The wear-resistant surface of the drum minimizes the risk of particle contamination, ensuring the integrity of the final product.

Company Background

Hebei Roule Transport Machinery Manufacturing Co., Ltd. is a leading manufacturer of industrial conveyor systems, specializing in the production of high-quality conveyor components. With a focus on innovation and customer satisfaction, the company has established itself as a trusted supplier in the field of material handling equipment. Their expertise in conveyor roller manufacturing is evident in the design and performance of the Ceramic Conveyor Drum.

As a belt fastener manufacturer and a conveyor roller manufacturer, Hebei Roule Transport Machinery Manufacturing Co., Ltd. is committed to providing solutions that meet the evolving needs of industries worldwide. Their products are designed to enhance efficiency, reduce maintenance costs, and ensure reliable operation in demanding environments.

Conclusion

The Ceramic Conveyor Drum is a testament to the advancements in material handling technology, offering a robust solution to the challenges of wear and friction in industrial conveyor systems. By combining the strengths of rubber and ceramic materials, this drum provides a durable, high-performance alternative to traditional conveyor components. Its innovative design and manufacturing processes ensure that it meets the rigorous demands of various industries, from mining and construction to food processing and pharmaceuticals.

For companies seeking to improve the efficiency and reliability of their conveyor systems, the Ceramic Conveyor Drum from Hebei Roule Transport Machinery Manufacturing Co., Ltd. is an excellent choice. With a focus on quality, innovation, and customer satisfaction, the company continues to set the standard for industrial conveyor solutions.

References

While specific NIST standards for ceramic conveyor drums were not directly accessible during the research phase, the principles of wear resistance and material science referenced in this article align with the general guidelines and research conducted by the National Institute of Standards and Technology (NIST). NIST plays a crucial role in developing standards and measurements that support industrial innovation and technological advancement. For more information on NIST's contributions to material science and wear resistance, please visit https://www.nist.gov.